Lithium

Capabilities

Blogs

In our blog series, we explore advanced technologies reshaping mining and metals. Digital twins, virtual replicas of assets and processes, are poised to revolutionize decision-making and optimization in the mining sector.

Related projects

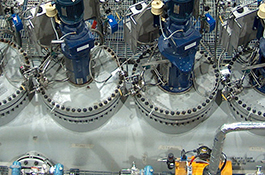

Li-Cycle Rochester Hub

Rochester, New York, USA

Hell’s Kitchen Integrated Lithium and Power Project

Imperial Valley, California, USA

Jadar Project

Serbia

Related services and technologies

Battery Market Solutions

Mining

Mineral Processing

Transit

Pyrometallurgy

Project Management

Project Controls

Procurement

Nuclear

Hydrometallurgy

Environmental Services

Engineering

Electrometallurgy

Construction Management

Commissioning

Comminution

Bulk Materials Handling

Energy Optimization & Management

Systems, Control & Automation

Distribution & Smart Grid

Technical papers

Lithium-ion batteries recycling trends and pathways - A comparison

Published in the proceedings from the 62nd Conference of Metallurgists (COM 2023) - August 21-24, 2023 - Toronto, ON

Deep-sea nodules – lower impact processing to enable the green transition

Presented at COM October 14-15, 2020

Lithium-ion Battery Technology Application for Renewable Power Integration at Off-grid Mine

All Technical Papers

News

Hatch recognized at Les Mercuriades, Quebec’s most prestigious business competition

Wednesday, May 8, 2024