Kingston Third Crossing (Waaban Crossing)

Optimizing design and delivery of the Waaban Crossing

City of Kingston

|

Kingston, Ontario, Canada

|

2018 - 2023

The largest transportation investment in Kingston’s history.

The first use of Integrated Project Delivery (IPD) for a bridge project in North America.

Multiple Award Winner for Project Excellence and Community Leadership

Design achievement with the tallest and longest NU precast, prestressed concrete one-piece girders in Ontario and the second in Canada.

Challenges

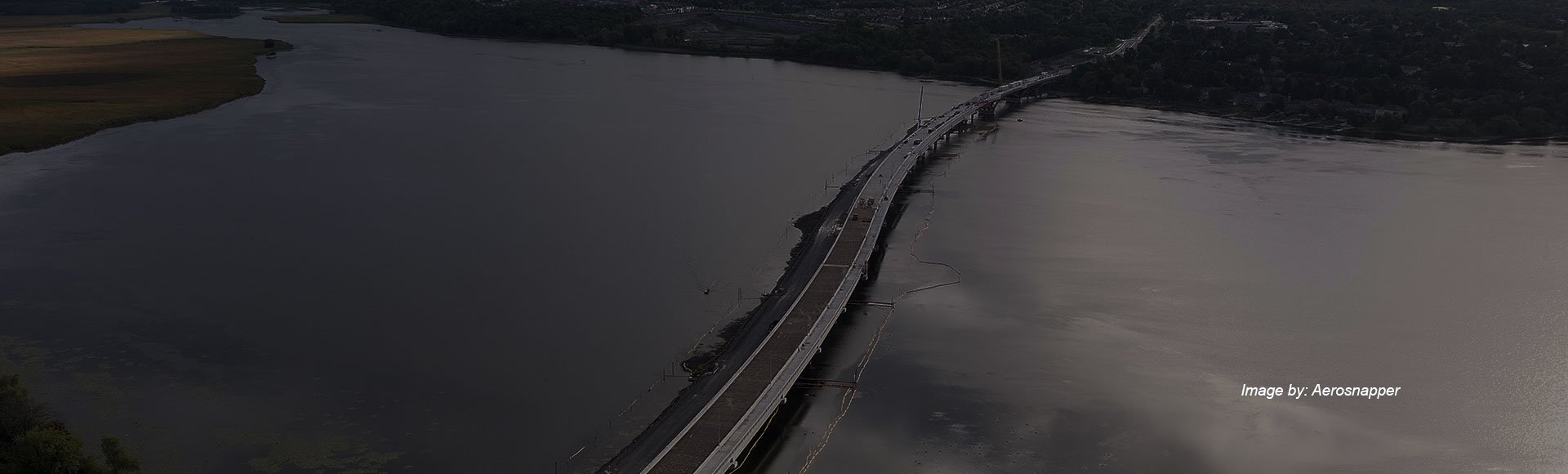

- As part of the City’s largest infrastructure project in modern history, the City of Kingston invested in design and construction of a 1.2-kilometer-long signature bridge over the Cataraqui River which forms part of the Rideau Canal, a United Nations Educational, Scientific and Cultural Organization (UNESCO) World Heritage Site and Federally regulated navigable waterway.

- This major investment aims to provide a much-needed third connection between communities on the east and west of the Cataraqui River, improve emergency services and response, provide an alternate route for the provincial Hwy 401, relieve traffic flow, promote active and public transportation alternatives, and accommodate future growth in the region.

- With $180 million in funding from all three levels of government, and a unique IPD Team partnership between the City, contracted design (Hatch and SYSTRA-IBT) and construction (Kiewit), and trade partners Bauer Foundations Canada and Walters Group firms, the project needed to minimize costs and risks as early and effectively as possible.

- Design and construction engineering had to consider the bridge’s proximity to the area where the Cataraqui River forms part of the Rideau Canal and other site-specific conditions.

Solutions

- The first bridge construction project to adopt the IPD model in North America. IPD projects aim to connect all partners together from the onset to set shared goals and maintain shared accountability and ownership to deliver the best project possible.

- Utilized Building Information Modeling (BIM) to improve design efficiency and productivity, and gave the City, contracted design and construction firms a better visual understanding of the project’s concept and scope.

- Leveraged BIM to lower project risks and costs, accelerate on-schedule delivery, improve overall integrated design, and minimize errors and rework.

Highlights

- Conducted bridge optimization through material selection and structural analyses to generate an estimated $12 million in savings to the target cost budget.

- Successfully navigated supply constraints and the rising price of steel by changing materials to concrete, lowering the bridge profile, and changing the main bridge section from an “above deck supported” arch to a “below deck supported arch”.

- Optimized the bridge design to reduce the overall in-water footprint by over 50% from the Environmental Assessment (EA) bridge design.

- Minimized visual impact to the Rideau Canal heritage site by partnering closely with Federal and Provincial environmental and heritage regulators, as well as Indigenous communities and surrounding residential communities.

- Implementation of a temporary rock causeway -trestle solution instead of using a full-length trestle to keep the Rideau Canal navigable between Spring and Autumn.

- 2023 Ontario Concrete Award – Infrastructure Award Kingston Third Crossing Bridge

- 2023 Canadian Consulting Engineering Award – Award of Excellence Transportation Category

- 2023 Transportation Association of Canada (TAC) – Infrastructure Achievement Award

- 2023 Association of Consulting Engineering Companies of Ontario (ACEC) – Award of Distinction

- 2022 Ontario Road Builders Association (ORBA) – Community Leadership Award

Project numbers

15.6 m bridge deck cross-section width, consisting of a two-lane vehicular roadway and a multi-use path.100-year design service life on various elements, exceeding the 75-year requirement for the Canadian Highway Bridge Design Code.

95 prestressed NU girders in total for the approach spans, with varying size, length and weight, and high-strength and extended durability requirements beyond the standard MTO requirements.

1,695 prestressed deck panels were installed to form the bridge deck.

3,300 tonnes of steel.

31,000 tonnes of concrete.

365,000 tonnes of gravel.

$18M+ in locally sourced material and contracts.

29,000+ local work hours sourced.