Hatch Integrated Tailings Management (HITM) 2.0 is here!

The next evolution of our Tailings Management platform.

Built for the complexities of modern mining, HITM 2.0 delivers:

* Native Databricks integration

* Enhanced GISTM conformance tools

* Streamline data workflows

HITM 2.0 brings the power of AI to a proven SaaS platform, helping tailings operations meet today’s challenges and unlock tomorrow’s opportunities.

Modern tailings management demands integration

Today’s tailings operations face growing pressure—from aging infrastructure and tighter budgets to evolving safety standards and rising scrutiny from communities. Teams are being asked to do more with fewer resources and the same outdated tools they’ve relied on for decades. Siloed systems, spreadsheets, and manual reporting contribute to reduced efficiency and increased exposure to risk.

Hatch Integrated Tailings Management (HITM) addresses these challenges head-on. As a purpose-built SaaS solution, HITM digitizes and connects the core activities of tailings operations—monitoring, communication, compliance, and reporting—so teams can respond faster, reduce uncertainty, and maintain continuity in the face of change. Designed to support the full lifecycle of tailings operations, HITM helps ensure nothing is missed when it matters most.

Start exploring HITM with our self-guided demo, or contact us to learn more.

Launch demoTransform the way you manage tailings

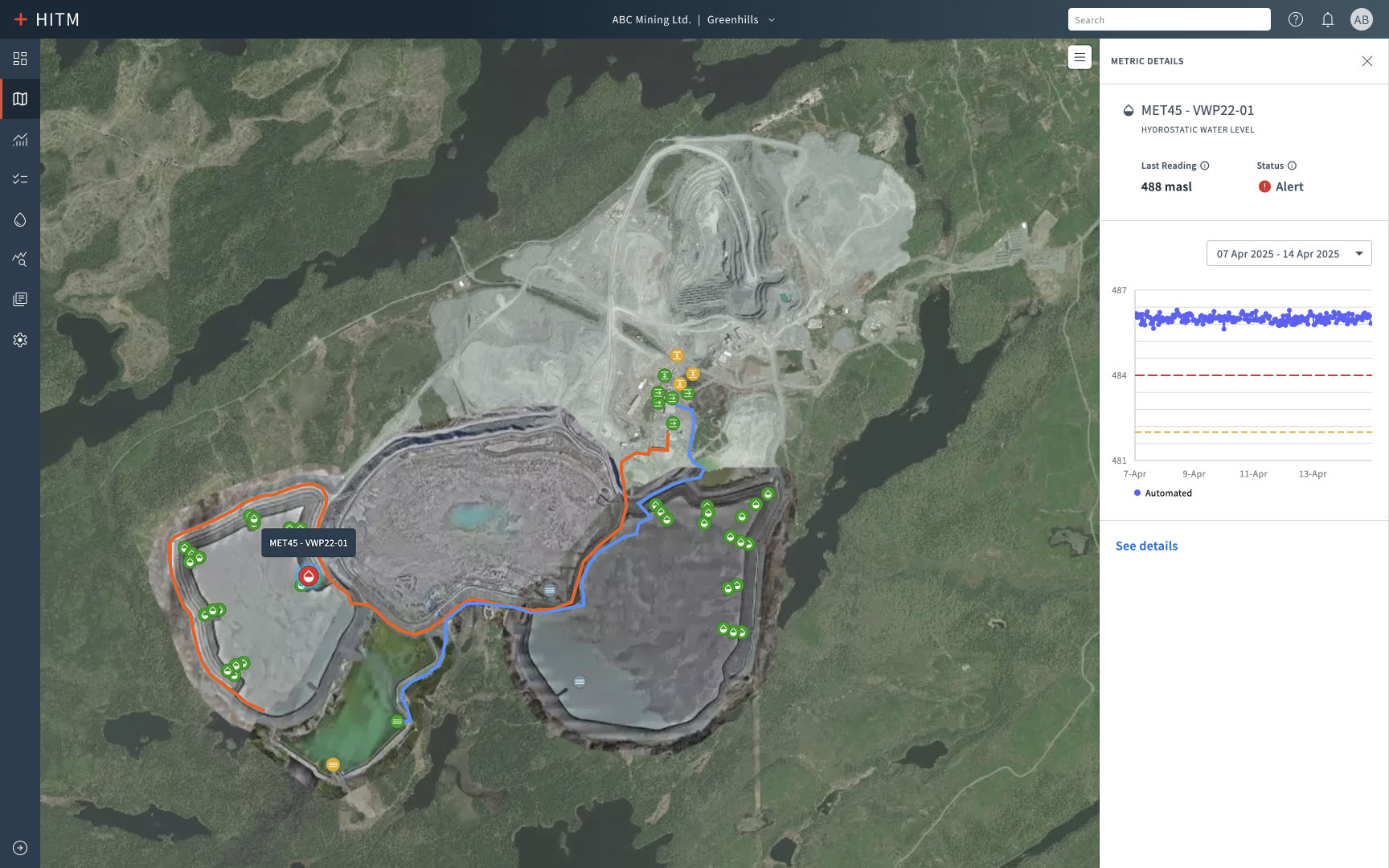

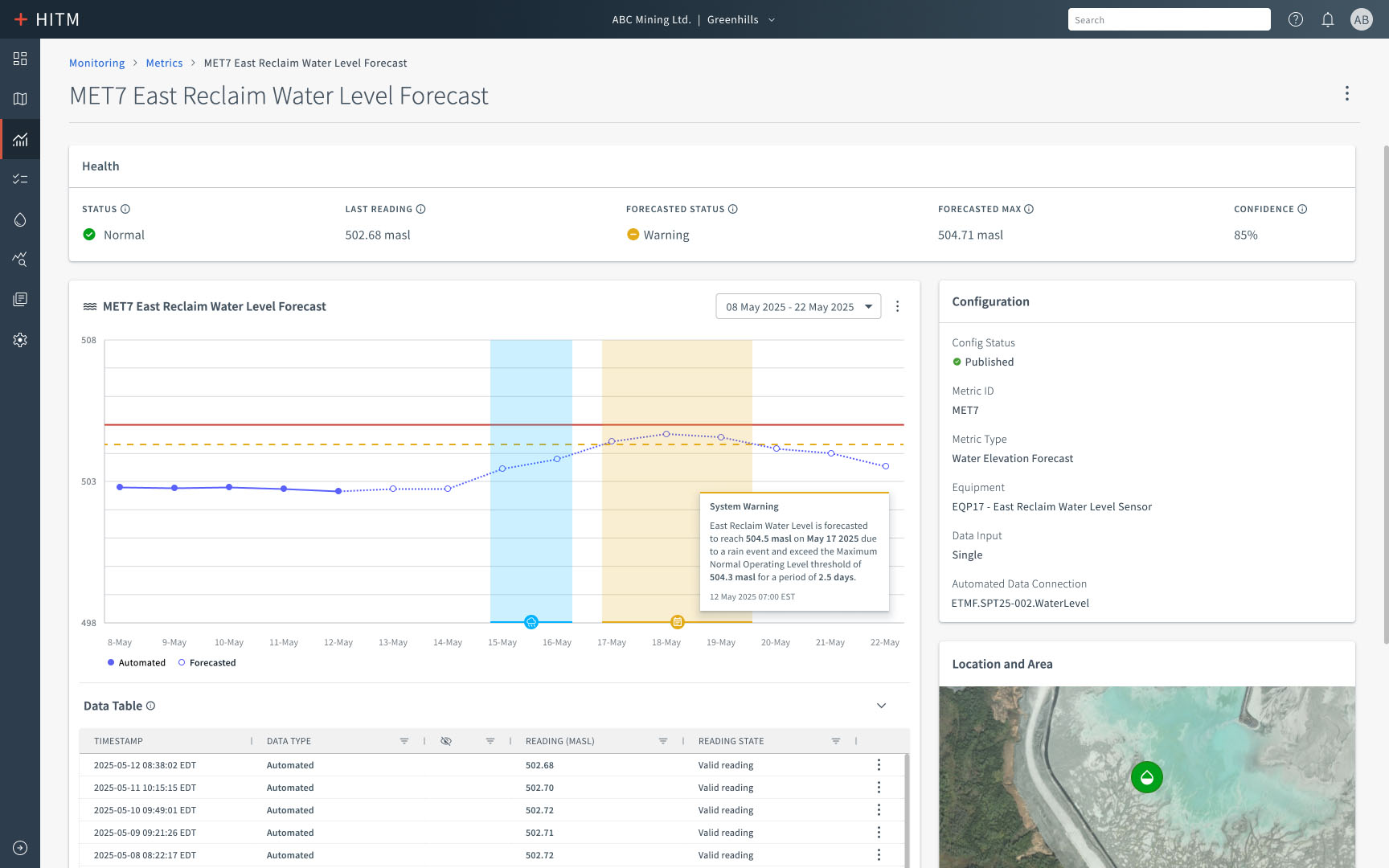

Make confident decisions with real-time, integrated monitoring

Isolated systems and siloed data make it difficult to see the full picture, slowing decision-making and increasing risk. HITM enables integrated, real-time monitoring with automated alerts, customizable thresholds, and seamless integration into your daily workflows. HITM ensures your team sees issues earlier, acts faster, and never misses a critical signal.

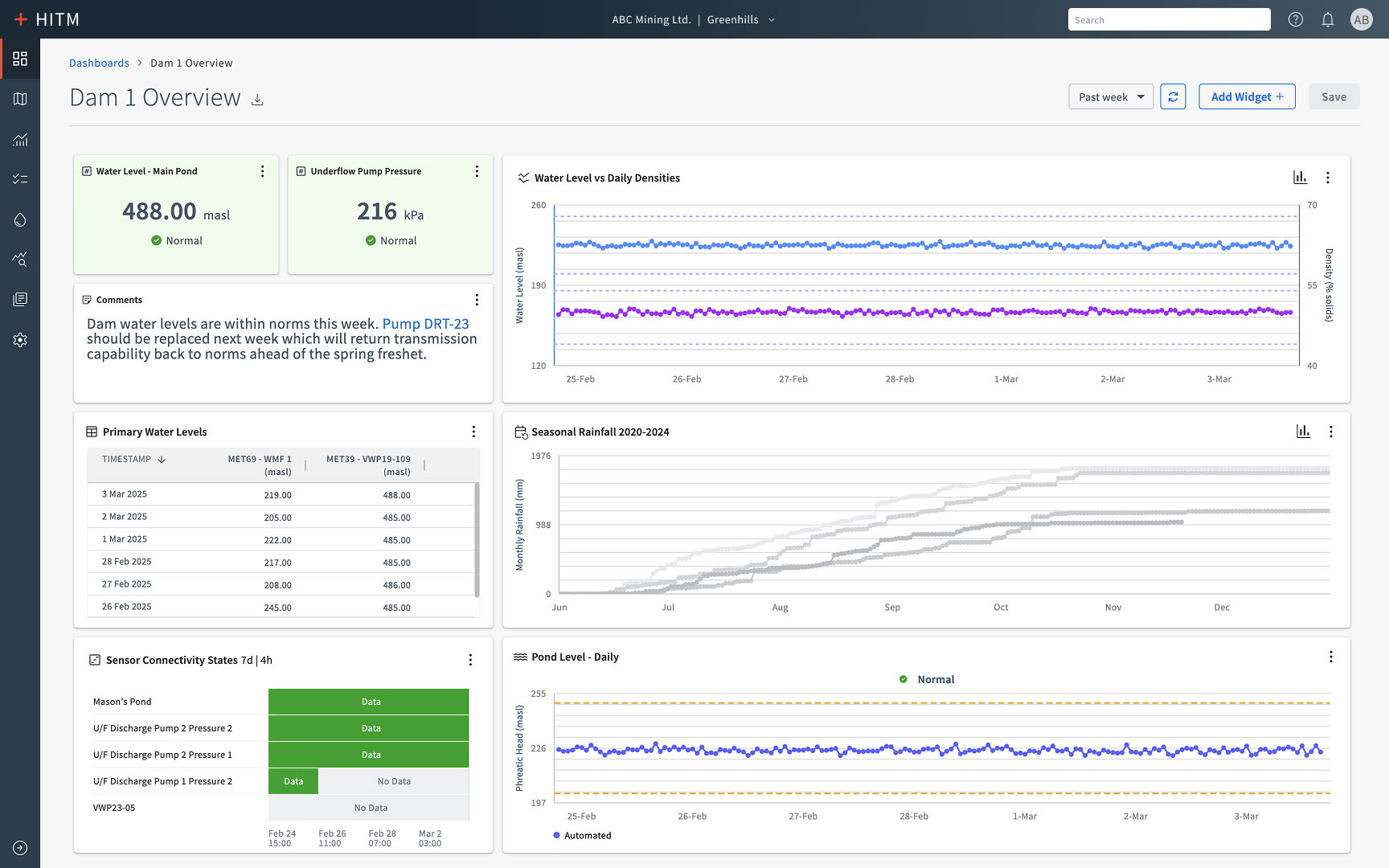

Move beyond spreadsheets with intelligent, digitized workflows

Spreadsheet-based workflows slow you down and expose you to errors. HITM digitizes these activities, making them faster and more reliable, while capturing clean, structured data for future analysis. With access to real-time data and the ability to communicate in context, HITM ensures everyone has the information they need, when they need it.

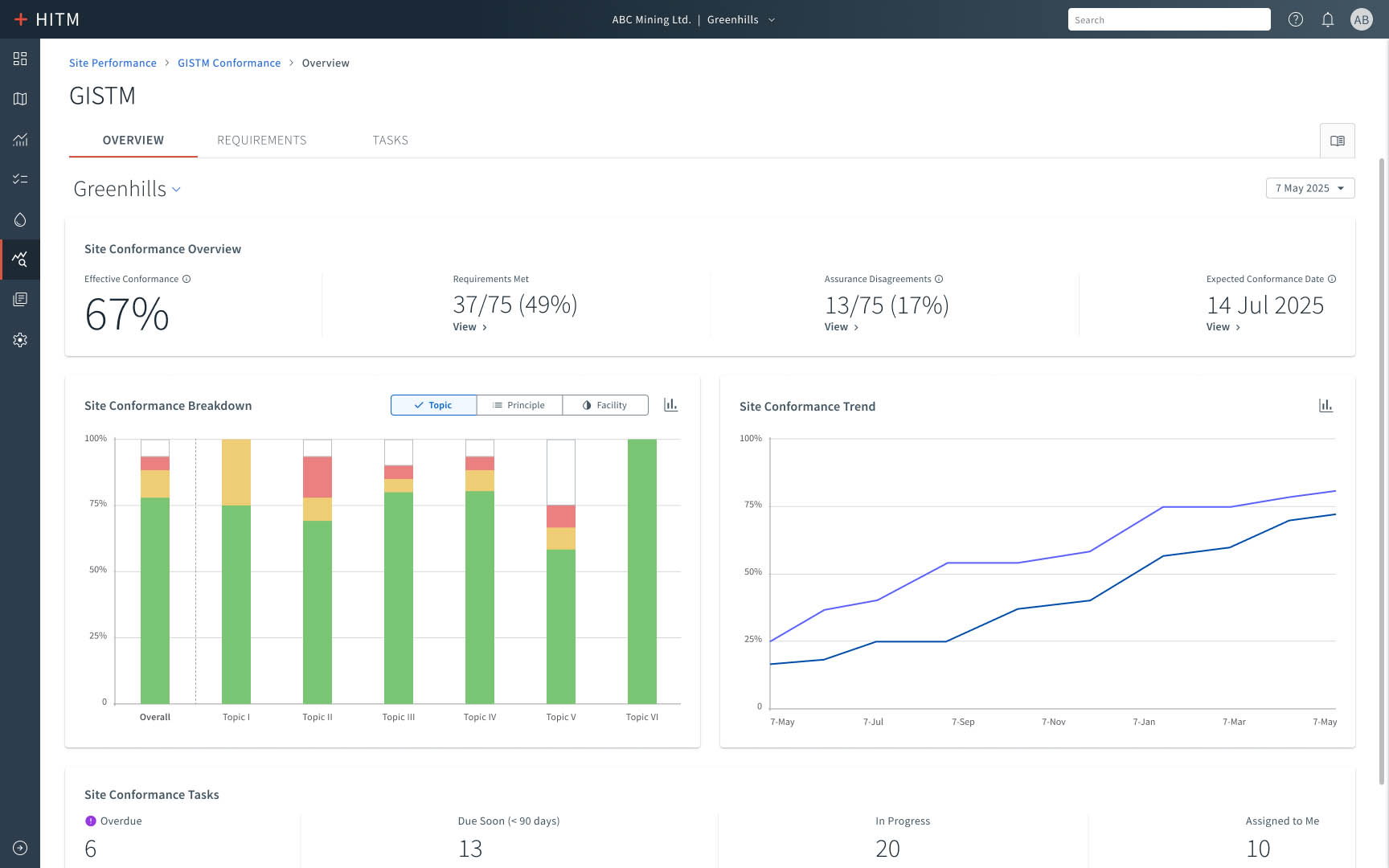

Stay audit-ready with simplified compliance management

Staying aligned with GISTM and other dam safety standards is a complex, ongoing challenge. HITM keeps your compliance activities centralized, auditable, and up to date, so you know exactly where you stand and what gaps you need to address. Whether you’re managing one site or 10, HITM ensures nothing slips through the cracks.

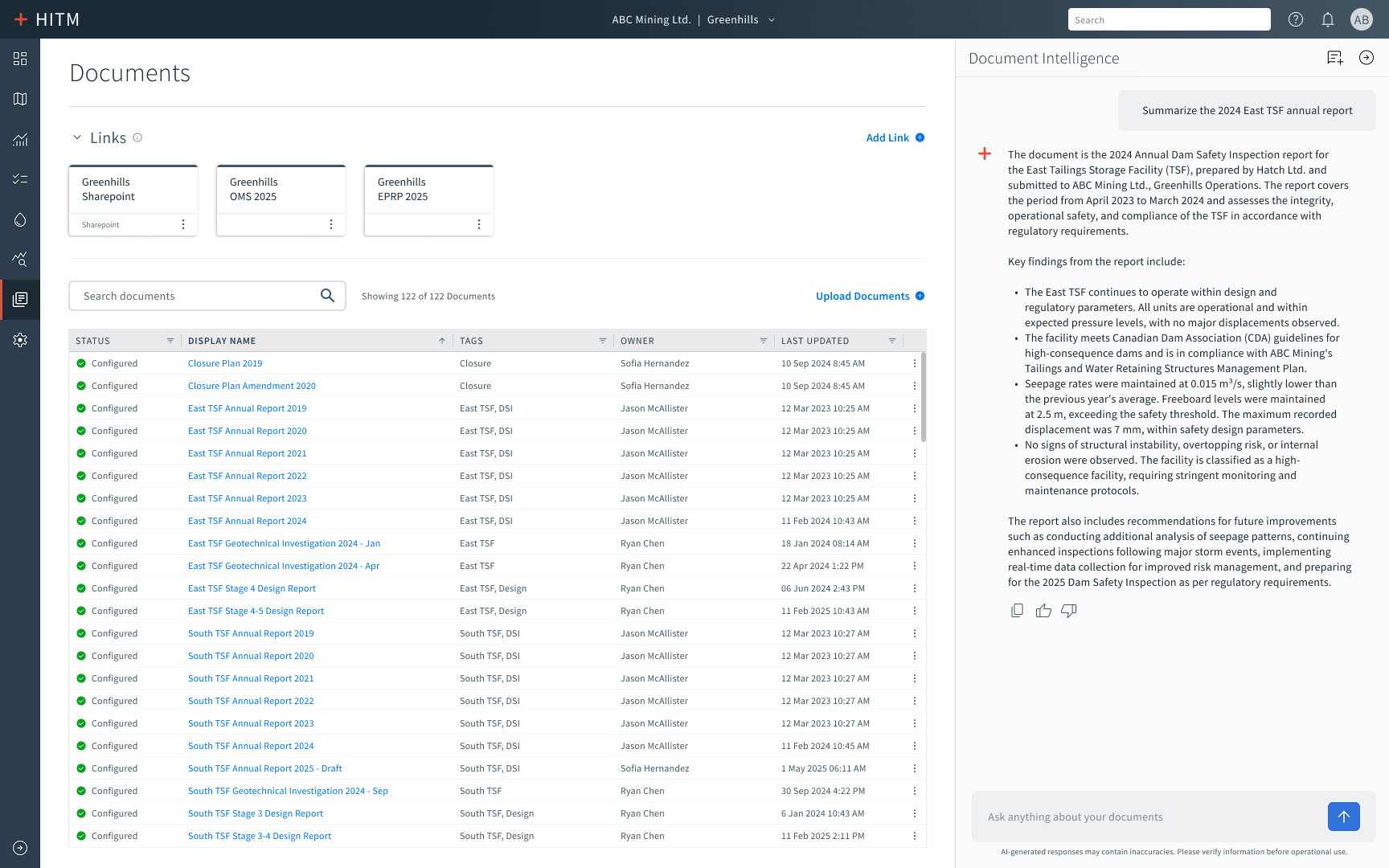

Protect operational continuity with a centralized knowledge base

Team turnover can create gaps in understanding that slow progress and increase risk. HITM preserves operational continuity by organizing critical site information in one place, so everyone stays aligned and decisions are based on a shared understanding of the site. With HITM, your site knowledge stays intact, no matter who’s on the team or how the plan evolves.

Unlock a smarter future with structured, AI-ready data

Tailings sites generate a rich archive of operational data that often goes untapped. HITM unlocks this hidden value through structured data exports that enable advanced modeling and analytics, such as phreatic surface trend analysis and deposition forecasting, in your preferred platform. With HITM, your data doesn’t just record the past—it powers a smarter future.

Time is running out to comply with the GISTM standard. Are you ready?

Members of the International Council on Mining and Metals (ICMM) have until August 2025 to adopt the standard. If you're already feeling the pressure, you're not alone—HITM can help you fast-track your path to compliance.

Easy to adopt. Built to scale. Ready when you are.

Integrates seamlessly

HITM connects to 350+ sensor types to deliver standardized real-time data from your existing systems—no rip-and- replace required.

Scales to your needs

From smaller, single-TSF sites to large, multi-facility operations, HITM delivers value across every size and level of complexity.

Backed by experts

Our tailings experts work closely with your team through implementation and beyond to ensure you have the support you need.

Secure and trusted

SOC 2-compliant and built on Microsoft Azure’s enterprise- grade cloud, HITM ensures access is controlled and your data is protected.

HITM 2.0 The next era of tailings management starts here

HITM 2.0 brings the power of AI to a proven SaaS platform, helping tailings operations meet today’s challenges and unlock tomorrow’s opportunities.