Meltshop 4.0

Get actionable insights to bring more efficiency, predictability, and synchronization

Learn more

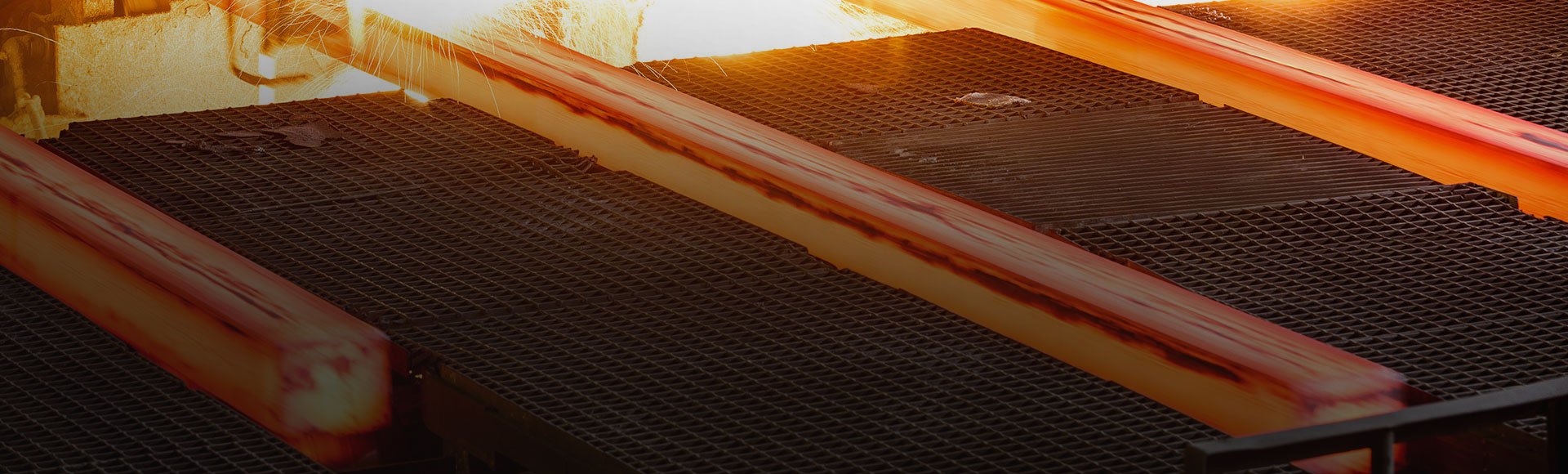

Meltshop 4.0 is built for the iron and steel industries to help generate significant reductions in production costs.

Steel producers are able to reduce carbon emissions and realize annual production savings of up to US$10 per ton.

Navigate with certainty using Hatch Meltshop 4.0

Built on Hatch’s 60+ years of experience in the metals industry and its no-code HxO Optimizer software, Meltshop 4.0 is a cloud-native, data-centric, and collaborative SaaS solution that delivers actionable insights, predictability, and simplicity for iron and steel production.

![]()

Conduct “what-if” scenarios

Conduct “what-if” scenarios to compare possible strategies and expected outcomes.

![]()

Raw material procurement

Determine optimal raw material procurement to manage cost.

![]()

Operating parameters

Define the most efficient operating parameter.

![]()

Synchronize

Synchronize across multiple sites.

![]()

Market demand

Match market demand to eliminate excess inventory of low-demand product.

![]()

Reduce carbon emissions

Pinpoint opportunity to reduce carbon emissions.

Interested in learning more?

Meltshop 4.0 unlocks value through optimization for a leading stainless steel manufacturer

Meltshop 4.0 can deliver up to $10 USD/ton savings in production costs.

Built-in intelligence based upon more than 60 years of experience operating in the iron and steel industries unlocks powerful capabilities – predictive analysis, meaningful elimination of unnecessary costs, synchronized and collaborative operations across multiple sites – meant to expand margins.