Challenges and complexities in midstream oil and gas

The realm of midstream oil and gas is shaped by a mosaic of ever-evolving challenges—unyielding regulations, intensifying public scrutiny, operations stretched across the most remote of frontiers. These challenges create complexities in the midstream oil and gas business that may seem endemic to the industry, but at Hatch, we create innovative solutions that make the seemingly complex, simple.

Mastering these intricate complexities requires visionary thinking and collaborative evaluation across processing, transportation, and storage. Together, we elevate industry success by driving profitability, minimizing impacts, and ensuring utmost safety.

Partnering with us means partnering for success. As your partner, we minimize risks, enhance stakeholder value, and execute projects seamlessly. With our expertise, we provide a comprehensive strategy from start to finish, which not only brings positive change to our partners, but to the environment, society, and the economy at large.

Capabilities

Hydrocarbon pipelines

Pipeline networks are quintessential for the safe transmission and distribution of hydrocarbons. The pipeline transportation channel calls for sophisticated designs that enable an uninterrupted supply of gases and fluids to transport safely and in a way that’s environmentally responsible.

Hatch has a long-standing partnership with Innovative Pipeline Projects Ltd. (IPP), a specialty pipeline engineering firm. Our combined expertise is comprehensive in all aspects of pipeline systems and the associated infrastructure—compressor and pump stations, field devices, tie-ins, valve stations, LACT units, trenching, and trenchless technologies.

Let us help you minimize the risk of working in extreme environments and remote locations, increase stakeholder value, obtain necessary regulatory approvals, and maintain pipeline integrity.

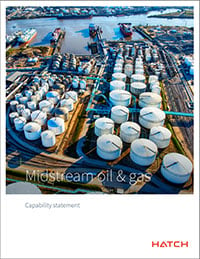

Storage and distribution

From above-ground storage tanks to salt caverns, we have a proven track-record of assessing, planning, designing, and constructing reliable hydrocarbon storage solutions. We specialize in large oil storage terminals with tank sizes ranging from a few barrels up to 500,000 barrels. Our in-house talent executes all ancillary facilities including the incoming and outgoing interconnections, meter manifolds, containment areas, and hydraulic and pumping designs.

Gas and oil processing

From dehydration to fractionation, to acid gas removal, we have the gas-processing knowledge to optimize your operation. Our expertise includes designing systems for water removal from gas and NGL liquid streams, and implementing amine and scavenger systems, and physical solvents to remove CO2, H2S, and mercaptans from natural gas. We can also recover NGLs from dehydrated gas streams through propane refrigeration, turbo expander plants, and lean oil absorption. Our oil processing expertise also includes battery design to process emulsion, LACT units for custody transfer, and blending facilities to meet shipping specifications.

Rail transport and dispatch

A lack of pipeline-takeaway capacity along with high-diluent demand and increasing costs have been pushing many producers to ship their crude oil and products by rail.

Rail terminals play an important role in the oil and gas transportation network. Efficient loading and offloading facilities support the seamless transfer of liquids between rail and other forms of transportation. Our team of in-house multidisciplinary engineers and architectural experts can help you design and construct a new terminal or transload facility from the ground up, or successfully execute work in an operating environment.

We have the solutions to improve overall terminal operability and efficiency, so your entire supply chain runs more smoothly.

Marine terminals

The world’s ports are the heart of a dynamic, interdependent oil and gas logistics network. They are the backbone of global trade. But aging infrastructure, lack of investment, increased regulations, and climate change impacts are challenging this critical supply chain. To manage these challenges effectively, a thorough understanding of the business drivers is needed, along with effective integration of the planning, design, construction, and operation phases, and finally, a comprehensive, innovative, and cost-effective approach to problem-solving. From new facility constructions to upgrades and expansions, we have the background and know-how to make your port and marine terminal project a success.

Industrial gas utilities and off-site facilities

The importance of robust and reliable utilities and off-site (U&O) systems are often underestimated. Yet steam, oxygen, power, and plant air systems are typically deeply integrated within the main process value chain, presenting risk if not properly designed.

Our deep expertise includes oxygen supply, steam systems, plant air, and power systems. We develop and deliver U&O systems that not only enable and support core process value chains, but add value through optimum efficiency and minimize redundancy in design and flexibility.

Liquefied natural gas processing

The potential for liquefied natural gas (LNG) as a transition fuel to lead the global shift towards a net-zero future is tremendous. But LNG projects are not always so easy. Remote locations provide tough challenges, and often have rigorous environmental standards.

For over 30 years, Hatch has worked to minimize these risks and increase stakeholder value through efficient project planning and execution, utilizing our extensive experience in a wide range of design services. Our core expertise in transportation, handling, conversion, and storage of LNG helps provide a comprehensive, integrated strategy for our clients.