Navigating challenges and embracing innovation in the transition to green metal

The challenge is clear: How do we implement significant technology change while balancing this with market and social expectations? In a conservative and capital intensive industry, perceived process risk hinders the acceptance of new technologies. But with mounting pressure to decarbonize, a shift is occurring. Global metal producers are seeking greener pathways and recognizing the need for specialized expertise in technology design, process scale-up, and low-emission green production technologies.

The commitment from responsible corporations to decarbonize has accelerated the advancement of electric furnace technologies and alternative production flowsheets that can take advantage of renewable energy. From steel to aluminium, we are partnering with clients and stakeholders to leverage our unparalleled expertise and resources to provide sustainable solutions that address the industry’s toughest challenges.

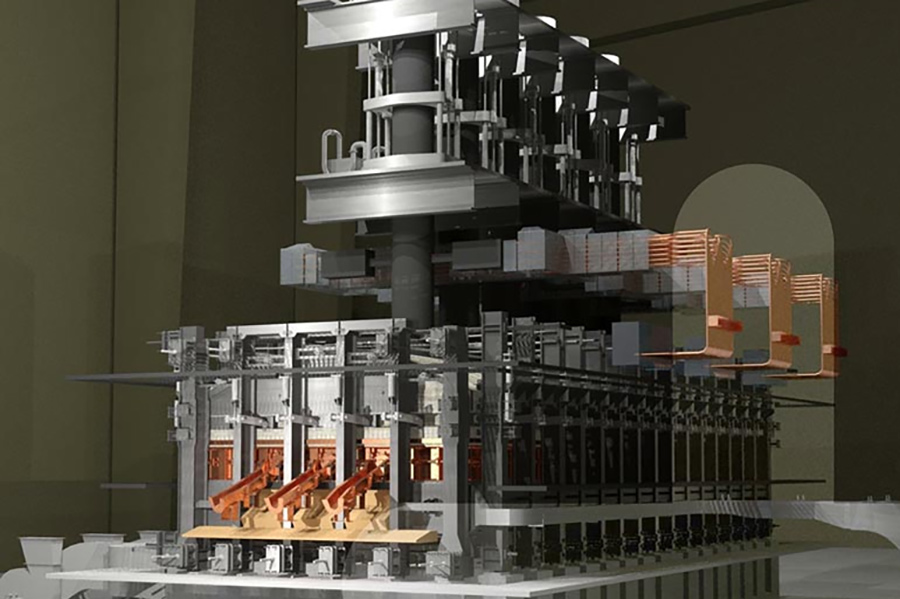

We’ve been ahead of the technology curve for years, as is evidenced by our electric smelting furnaces (CRISP and CRISP+ furnaces), which are now being adopted by the steel industry. When combined with direct reduced ironmaking technologies, the CRISP and CRISP+ smelting furnaces can decarbonize the iron and steel value chain by replacing fossil carbon with low-emission electrical power.

CRISP was developed nearly two decades ago to produce low carbon liquid steel from direct reduced iron (DRI) in one step, replacing carbon-intensive blast furnaces and basic oxygen furnaces. When coupled with the latest DRI technologies, CRISP can replace almost all the carbon to produce liquid steel with hydrogen. The newer CRISP+ furnace produces carbon containing hot metal that replaces blast furnace hot metal in basic oxygen furnace steelmaking or produces green pig iron for merchant sales.

The transition to green metals isn’t just about adapting new technologies; it’s a comprehensive transformation across the entire value chain. From initial concept design and implementation to asset management post start-up, our EPCM approach plays a pivotal role. Digital project delivery streamlines our design and planning phases, ensuring efficient resource allocation and waste reduction, especially for

multi-billion-dollar investments.

With the metals industries facing transformational change, project development requires a holistic approach that considers the entire value chain from feed to the final product portfolio. This is where our technological advantage, combined with deep subject matter and project implementation expertise, is most valuable.

The heart of green metal lies in electric furnaces powered by renewable energy sources. Our process experts work collaboratively with our climate change practice to align with global climate goals, develop competitive strategies, and ensure comprehensive global connectivity with other industrial sectors such as the automotive and battery industries.

For our green metal experts, it’s not speed to market that matters most, but speed to innovation and successful new technology implementation. We’re addressing the most daunting global challenges by consistently taking a forward-thinking approach and fostering solutions in all we do. With foresight and intention, together we’re leading the way to a cleaner, more sustainable future.

Forging the Future: Decarbonizing the Steel Industry Blog Series

- SMRs and the future of sustainable steel

- Iron ore: The decarbonization transformation

- Navigating the waves: Steel industry's raw material challenges in the green transition

- Navigating challenges and embracing innovation in the transition to green metal

- Pioneering the path to green steel: Challenges, innovations, and the road ahead

- Beyond the Furnace: Elevating GHG Reporting in the Steel Sector

Peter Weber

Regional Director, Metals

Peter Weber joined Hatch as part of the Hatch Küttner merger in 2023, assuming the role of regional director of metals for Hatch’s European region. Peter holds a PhD in pyrometallurgy from the University of Witwatersrand in South Africa.