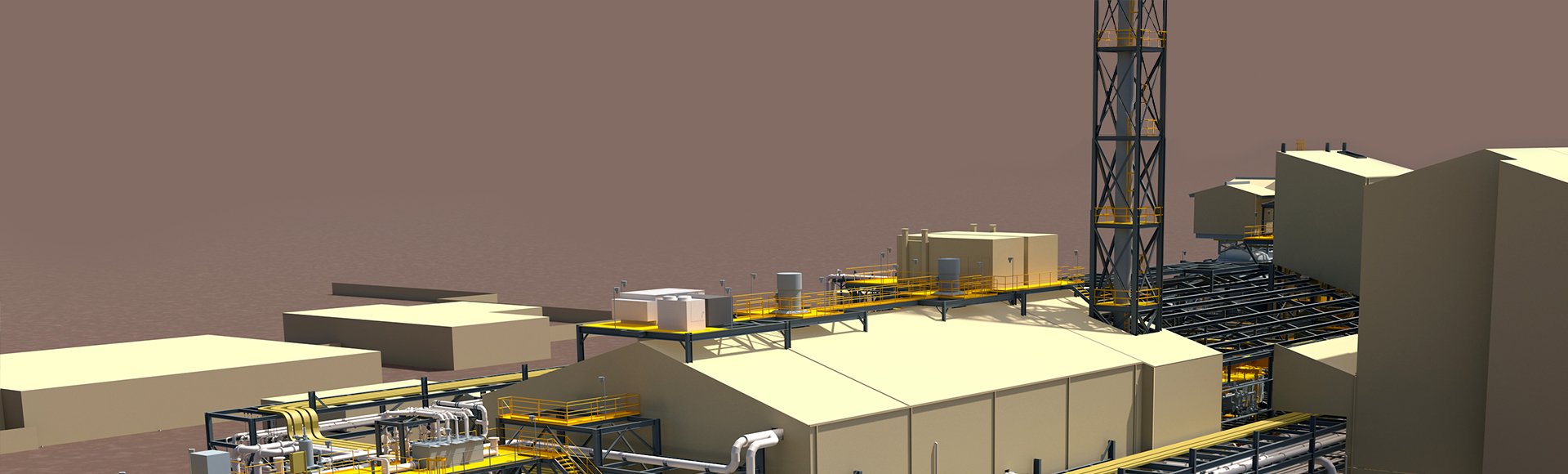

Phosphoric Acid Plant Expansion

Expanding Simplot’s Rock Springs phosphoric acid plant

J. R. Simplot Company, Simplot Phosphates LLC

|

United States

|

2011–2014

540,000 man-hours were exceeded with 0 LTIs.

10% increase in on-stream time at phosphoric acid plant.

10% below the project budget.

Challenges

- Simplot Phosphates had previously implemented plant-expansion projects that increased phosphoric acid production and plant on-stream time.

- Operating limitations arose due to lower-quality phosphate-rock feed and process scaling issues with the phosphoric acid filters, resulting in excessive downtime for filter washing.

- The plant needed debottlenecking to increase its P2O5 production capacity by 10%.

- This heavy brownfield project was constructed within an operating phosphoric acid chemical plant.

Solutions

- Provided full EPCM services, and employed detailed design services for the conceptual, prefeasibility, feasibility, and detailed engineering phases of these expansion projects, including commissioning.

- Eliminated the existing cooling tower and shifted the plant heat-load to the existing gypsum stack and cooling pond systems.

- Hot process water from the new blend-tank system lengthened filter-wash cycles from every two days to every six days, increasing the plant's on-stream time by over 10%.

- Improved evaporator on-stream time, with evaporator-washing frequency decreasing from once per week to once every three weeks.

- Eliminated scaling issues by having hot pond water recycled through the pond water-supply pump intakes, using the pumps and pond water-supply lines to the phosphoric acid plant.

Highlights

- Designed a new phosphoric acid reactor and reactor vacuum system to achieve higher production rates and greater stability than the existing reactor.

- Eliminated the phosphoric acid plant cooling tower and the process heat load was successfully shifted to the gypsum stack and existing cooling pond.

- Higher pond water temperatures reduced scaling and provided hot process water for filters and process equipment.

- A total of 975 contractor personnel were given safety training for site access. There were no lost-time incidents on this project.

- The project was executed with final costs at 10% below the project budget.

“Hatch is executing EPCM at Simplot’s Rock Springs facility for phosphoric acid plant expansion projects with an overall TIC of $160 million. We chose Hatch for this work due to their process expertise, commitment to safety and quality of engineering. Hatch is providing a high level of service and is working closely with us to incorporate our maintenance and operations requirements into the final design. We are currently on budget and schedule and we look forward to a successful start-up in 2014.”

Project numbers

US$134 million project capital value80-ft. diameter, 44% P2O5 phosphoric acid clarifier

4-day increase in filter on-stream time

975 contractor personnel safety-trained for site access