Zimplats Smelter Expansion

A smelter expansion powering progress for Zimbabwe

Annual review 2025

Project

From the cars in our driveways to life-saving surgical technologies, platinum group metals (PGMs) are essential to modern life. And in Zimbabwe, Zimplats, a proud subsidiary of the Implats Group, has emerged as the country’s leading PGM producer.

With a deep commitment to sustainability, community development, and operational excellence, Zimplats embarked on a transformative journey to expand the smelting capacity and implement a new SO2 abatement plant at its Selous Metallurgical Complex (SMC), located 80 kilometers southwest of Harare. At the center of this initiative was a state-of-the-art 38-MW Hatch furnace, which tripled the smelting capacity and positioned SMC as the PGM processing facility of choice in Zimbabwe.

- 2nd largest PGM furnace in the world

Zimplats Smelter Expansion

As a long-standing partner of Zimplats for more than 25 years, we brought deep knowledge of the smelter and world-leading expertise in PGM smelting and SO2 abatement. We delivered project management, controls, risk management, engineering, procurement, quality assurance, health and safety management, construction management, and commissioning services, overseeing every phase of the expansion.

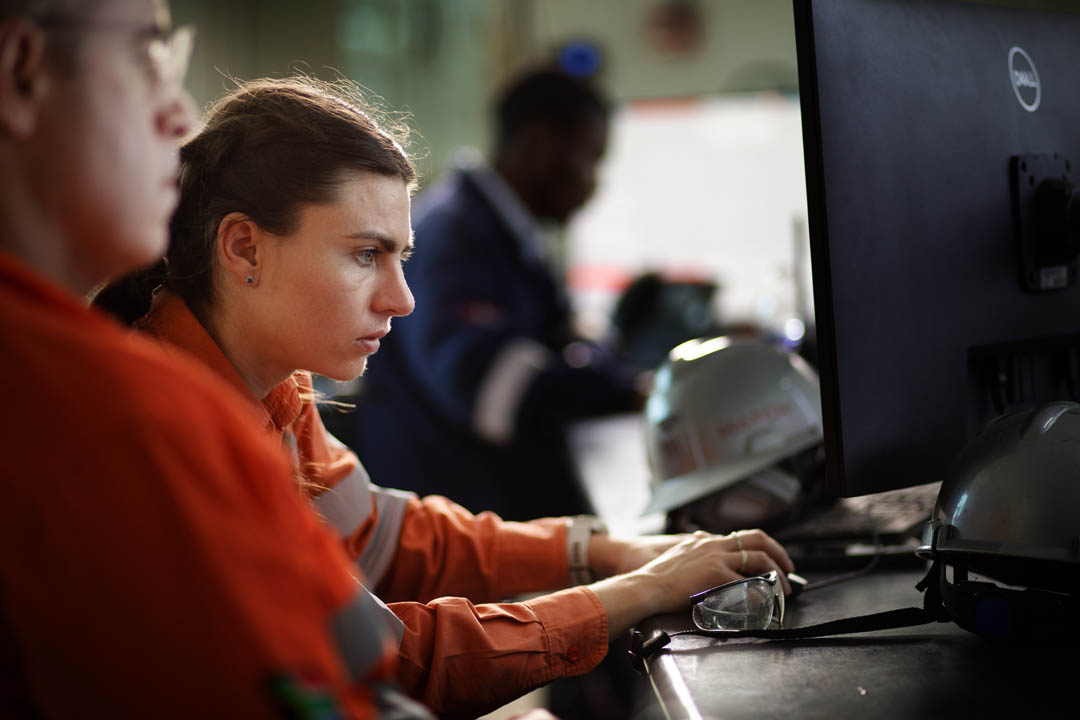

Space at the existing SMC smelter was limited and the upgrade had to be executed and integrated without halting production. Accounting for these complexities, we developed a tailored approach for the layout and flowsheet as well as construction and commissioning activities to ensure minimal interference. And with the smelter operators actively working in the producing plant, we also established a plan to train those same operators on the new plant, highlighting differences between the old and new operations, and accounting for hand-over between the commissioning and operations teams.

The $400-million smelter expansion consisted of a wet concentrate feed system, a 45-tonne-per-hour flash dryer, a 38-MW Hatch furnace, two 12’ by 24’ Peirce-Smith converters, a new compressor house to supply plant and instrument air to the expanded smelter, a cooling water plant to provide cooling water to the furnace and other plant users, raw and potable water storage and distribution plants, a slag granulation system for the new furnace and an integrated slag handling system for both the old and new furnaces, and a converter aisle extension to allow for optimal production and maximized redundancy between the existing furnace and converters and the new ones.

- 135,000 TO 380,000 TONNES of concentrate per annum

Zimplats required that the project be fast-tracked to meet their growing demand and overarching business plan, and we were entrusted to lead the way. The project moved from the feasibility study in 2021—without any preceding phases—to execution in less than a year and final hot commissioning was completed in December 2024.

Success hinged on precise logistical planning, early engagement with key technology partners, and close collaboration between the Hatch and Zimplats teams. Hatch and Zimplats worked closely with suppliers to optimize engineering, fabrication, and delivery schedules. We sole-sourced and appointed technology partners as early as the feasibility study, allowing for overlapping project phases and seamless coordination of construction and commissioning.

The global COVID-19 pandemic was at its peak during project initiation and feasibility study. With teams spread across South America, Canada, and South Africa, all design reviews and execution planning had to be conducted virtually. It wasn’t until January 2022 that the team met on site for the first time to begin execution.

Global supply chain disruptions, geopolitical tensions, and rising steel prices added further complexity. In September 2023, Zimplats made the strategic decision to defer Phase 2 of the SO2 abatement plant to 2028, focusing efforts solely on the smelter expansion. This required agile planning to reconfigure shared utilities and implement interim emissions control measures.

With full focus on the smelter, we delivered the furnace, flash dryer, Peirce-Smith converters, and all supporting systems. The result is a near threefold increase in smelting capacity from 135,000 to 380,000 tonnes of concentrate per annum, enabling Zimplats and the Implats Group to meet future production targets.

- 5M site hours >1,000 local jobs

Throughout the project, our integrated digital delivery tools ensured real-time tracking of engineering, scheduling, estimating, and construction.

Despite the odds, the project moved from board approval to first matte tap in just under three years, logging more than 5 million site hours with only one lost-time injury, a testament to ours and Zimplats’ shared commitment to safety and excellence.

The new furnace has operated at the required operating factor since commissioning with no concentrate stockpiles or exports. The expanded smelter now stands as a technological legacy powered primarily by solar and hydro energy, and representing the future of sustainable mining in Zimbabwe.

The project created more than 1,000 construction jobs for local communities and reinforced Zimplats’ role as a catalyst for economic development. Looking ahead, Zimplats and Hatch are preparing for the next phase: construction of the SO2 abatement plant, scheduled to be in operation by the end of 2028. Once operational, it will produce high-strength sulphuric acid for local fertilizer production, supporting Zimbabwe’s agricultural sector and reducing environmental impact.

Explore more: Annual review 2025

- PROJECT

East Harbour Transit Hub

- INSIGHTS

Efficiency by design: Delivering Capital projects in today’s markets

- PROJECT

AP60 Expansion Project

- INSIGHTS

Ushering in a new era of intelligent risk-based decision making in construction

- PROJECT

Zimplats Smelter Expansion

- INSIGHTS

Contractor delivery for successful project outcomes

- PROJECT

Hunter Power Project

- INSIGHTS

Are you leaving value on the table after the build?

- INSIGHTS

AI breakthrough in mineral processing unlocking millions in value

- INSIGHTS

The faster, the better? The intersection of rapid delivery and responsibility

- PROJECT

Newmont’s Yanacocha Water Transition Projects

- PROJECT

Wataynikaneyap Power Transmission Project

- PROJECT

Sound Transit’s System Expansion