Build better batteries: Part 2

The overconfidence trap: How to realign battery projects when optimism outpaces readiness

How to realign battery projects when optimism outpaces readiness. Explore in more detail in Part 2 of the Build better batteries video series.

Hidden pitfalls in the battery value chain

Under tight timelines, teams often compromise on quality systems. Material inspections are rushed, pilot runs are abbreviated or skipped, and process validation gets pushed into post-launch.

We, as an industry, understand that what looks good in a controlled test environment doesn’t always deliver at scale. So why does this misalignment persist?

First, let’s take a look at the two buckets that characterize project failures:

- The mismatch between test data and field conditions, exposing performance shortfalls. This includes impurities or incompatible coatings, which trigger side reactions in the cell; and inconsistencies across material lots from new suppliers, causing yield loss and rework.

- Inaccessible data, leading to uninformed or partially formed decisions. This triggers undesired risk assumption, causing cost escalation or creating design-gaps which are only realized in the chaos of construction.

These failures don’t stem from a single catastrophic event. They’re the result of quiet misalignments that accumulate until they become visible at scale.

Project leaders know something’s wrong long before it’s publicly known or acknowledged. The question then becomes: Why don’t they course-correct?

Is it because they’re afraid to speak up? Is it because the sunk costs, internal politics, and supplier pressure make it too difficult? Is it because there’s insufficient time? Or is it a combination of all these issues?

Hidden pitfalls in the battery value chain

- Teams confuse construction speed with readiness success.

- Procurement outpaces engineering, leading to mismatches and delays.

- Lessons from R&D and pilot phases don’t translate into scaled production.

- Automation is deployed as a solution to efficiency, not consistency.

- Plant integration breaks down not because of conflict but because of omission.

- Delayed recognition of failure.

“Project leaders know something’s wrong long before it’s publicly known or acknowledged.”

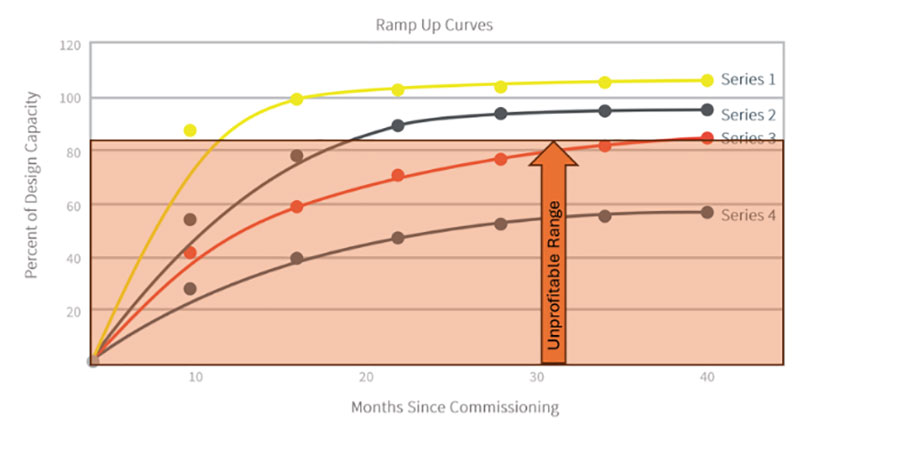

At their core, these patterns point to a recurring breakdown: a gap between perceived and actual readiness. When pressure mounts—whether from investors, off-takers, governments, or market expectations, projects are often pushed forward based on symbolic milestones rather than functional ones.

Each of these failure modes compounds the others. Procurement outruns engineering when timelines are rushed. Automation misfires when upstream processes remain unstable. And when pilot data is ignored or lacking, teams enter production with blind spots that dashboards can’t fix.

Delays in recognizing failure aren’t due to incompetence, but to optimism without discipline. Early signals are often visible but not acted upon, either because acknowledging them feels too politically risky or because there’s no structured way to escalate without blame. In a culture of optimism, often the person who sounds the alarm bell is labelled a pessimist.

In other words, speed isn’t the enemy. The true nemesis is misplaced confidence. The most successful battery projects aren’t those that avoid pressure, but those that manage it intelligently.

Patterns present solutions

We need to move beyond simply testing basic performance by simulating real-world stress and running integrated trials at pilot scale, with production-grade materials, in realistic environmental conditions.

To manage this, manufacturers need to shift from reactive decisions to proactive precision.

De-risking through research and development

In recent months, there has been a slowdown in electric vehicle (EV) sales. Many of the lithium-ion plants that were constructed are not operating at full capacity due to insufficient demand.

Sourcing decisions can't live in isolation; R&D, quality, engineering, and operations must work together to validate each input within the context of the full system. The goal isn’t perfection—it’s predictability, requiring an understanding of how a material behaves before establishing a production schedule.

Financial runway meets technical runway

One of the most under-discussed risks in battery innovation is the financial pressure to scale prematurely. Many startups fail not because their chemistry is flawed, but because they didn’t have the capital or the patience to test, iterate, and harden their process.

Strategic partnerships and public funding programs can help. DOE grants, EU battery innovation initiatives, and government-backed pilot facilities can create the breathing room needed to do it right. But funding must be tied to technical milestones, not commercial ambition.

The four pillars of resilient battery sourcing

Through years of work with manufacturers and material suppliers, we’ve identified four guiding principles that consistently reduce technical risk:

- Validate before you scale. Pilot under real conditions, not ideal ones.

- Partner across functions. Procurement is a team sport—R&D, ops, and quality all need a seat at the table.

- Keep it simple. Focus on one or two key products, instead of falling into a complex web of diversified offerings.

- Pressure-test everything. Model edge cases. Simulate degradation. Plan for the worst-case scenario.

We are entering a new wave of battery manufacturing—one defined not just by how fast you can build, but how smart. Success will go to those who treat scale-up as a system challenge, who anticipate failure modes before they surface, and who resist the temptation to trade short-term speed for long-term survivability.

In the battery economy, it’s not just what you build—it’s what you build with it.

Build better batteries

- Part 1: Battery projects are failing. Here's how to fix them

- Part 2: The overconfidence trap: How to realign battery projects when optimism outpaces readiness

- Part 3: Build better batteries: Don’t just do it. Do it right

- Part 4: Build better batteries: Don’t Risk accumulation and the reality of operational readiness

Steven Angel

Senior Process Engineer, Battery Materials

Dr. Steven Angel brings over 14 years of expertise in process and materials engineering, with a strong focus on the development and quality control of battery materials. He holds a B.Sc. and M.Eng. in Chemical Engineering, as well as a Ph.D. in Process Engineering. Steven has played key roles in numerous battery material projects—including NMC, LFP, graphite, and silicon—as a Process Lead, Project Manager, Interface Manager, and Subject Matter Expert.

Ashleigh Warren

Practitioner, Battery Materials

Ashleigh Warren is a process engineering practitioner at Hatch, where she has been contributing to battery materials projects since graduating with a degree in Chemical Engineering. Her work has focused on battery recycling, particularly NMC black mass, and she has gained experience in graphite purification, MHP refining, and the processing of coal and phosphate materials.