Westinghouse AP1000™ Nuclear Plant Program

Engineering and design services for Westinghouse AP1000™ pressurized water reactor

Westinghouse Electric Company

|

USA and China

|

2010-2012

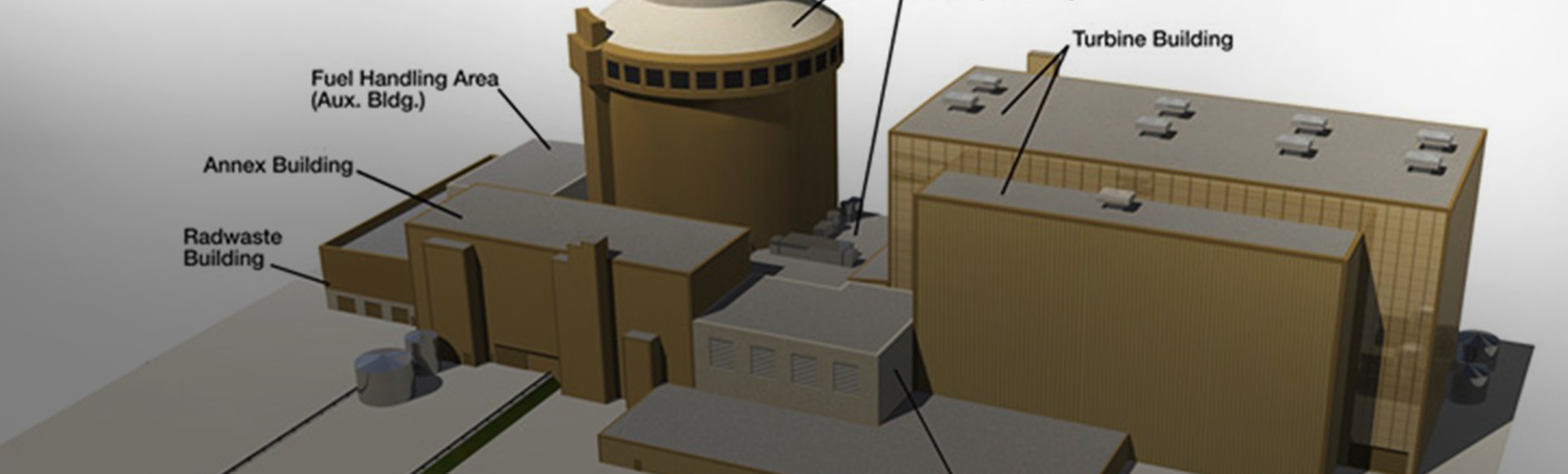

Site-specific design enhancements for future AP1000™ PWR units.

Services for the first US units and Chinese units.

Designs reviewed for safety, operability and maintainability.

Challenges

- The Westinghouse AP1000™ pressurized water reactor is an advanced 1100-MWe nuclear power plant. It is a modular design that uses 50% fewer valves, 35% fewer safety grade pumps, and 80% less piping than previous nuclear plants. It also features a passive safety design.

- Six utilities have chosen the AP1000™ PWR for use in seven combined construction and operating license (COL) applications to the US Nuclear Regulatory Commission (NRC) for a total of 14 AP1000™ units, including six for which engineering, procurement and construction contracts have been signed.

- Additionally, four units are under construction at two sites in China, with the first unit to come online in 2013.

Solutions

- Retained to provide engineering and design services to assist in the development of construction drawings for the containment and auxiliary buildings.

- Supported Westinghouse’s structural, piping, layout, mechanical modules, and structural modules groups for a 17-month period, which began in January 2010.

- Provided a team of engineers to perform finite element analyses of key structural floor and modules.

Highlights

- Services included 3D PDS modeling and 2D CAD services.

- Designs reviewed for safety, operability and maintainability, even with no direct site involvement.

- Staff assigned in Westinghouse’s office and Hatch’s Pittsburgh office.