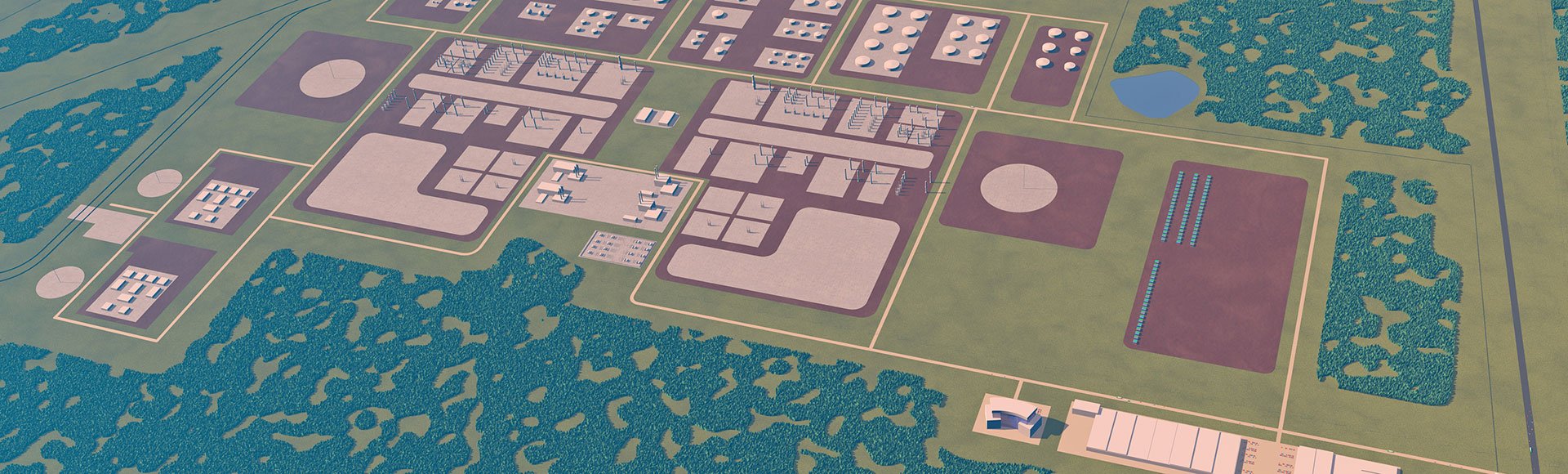

Kitimat Clean Refinery

Kitimat Clean Inc.

|

Canada

|

2014

World's largest and greenest GTL refinery when built.

550,000 barrels per day of diluted bitumen.

CO2 emissions among the lowest for any heavy crude refinery.

$22 billion estimated capital cost.

Challenges

- Kitimat Clean Inc. set out to build the largest integrated gas-to-liquids refinery in the world.

- Using state-of-the-art design to process Alberta bitumen (extra-heavy oil with 8–10 API gravity), the refinery aimed to have the lowest carbon emissions of any in the world and remain economically viable.

- The facility would refine products for export, including ultra-low sulfur diesel and superior gasoline that meets Euro-5 equivalent specifications.

Solutions

- Completed a feasibility study, including design engineering and capital-and-operating cost estimates, to develop and technically validate a process configuration.

- Designed a refinery with zero coke and fuel-oil production, minimal water intake, and zero water disposal by integrating it with GTL technology.

Highlights

- Novel technologies employed to minimize NOx, SOx, and CO2 emissions.

- CO2 emissions per barrel are among the lowest for any refinery processing heavy crude.

Project numbers

550,000 barrels per day of diluted bitumen processed460,000 barrels per day of refined fuels produced

3,000 people employed once plant operational