Challenges

Rising energy prices and the urgent need to reduce greenhouse gas emissions (GHG), continue to amplify the importance of Waste Heat Recovery (WHR) as a cornerstone for sustainability in energy intensive industries.

WHR enables facility operators to use heat that would otherwise be released to the environment, resulting in significant energy savings, reduced emissions, lower operational costs and overall more sustainable and environmentally friendly operations.

Increasingly, industry leaders across the globe in sectors such as metals, cement, power and oil and gas, are partnering with Hatch to maximize the utilization of available resources and minimize waste.

Capabilities

By combining our world-leading process domain expertise with our deep experience in industrial gas cleaning and heat transfer systems, we design and implement customized, integrated WHR solutions, using the most suitable and cost-effective technologies available.

In addition to our role as integrators of customized Waste Heat Recovery (WHR) systems, we also offer technology packages for industrial process applications. These include our Ecoflow heat recovery solutions and our proprietary Ecostat Heat Exchangers, both designed to be seamlessly integrated into a wide range of industrial operations.

Ecoflow

Our Ecoflow solutions are developed in collaboration with leading industrial heat exchanger equipment suppliers to harvest waste heat from liquid, gaseous, and solid process streams. The recovered energy is then repurposed for beneficial applications, including process heating, steam generation, and combined heat and power generation.

Ecostat

Our Ecostat heat exchanger technology is a robust heat transfer solution tailored to the efficient recovery of low-grade heat in a safe and low-cost manner.

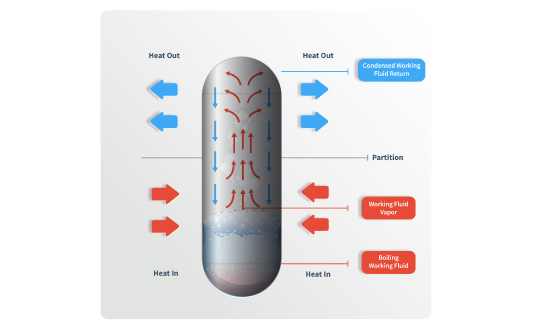

ECOSTAT heat exchangers comprise heat pipe bundles, filled with a working fluid, that span the hot and cold gas flow paths. These bundles are enclosed within a complete assembly that includes a structural casing and tube sheets, , a gas-tight partition plate that separates the hot and cold sides, and inlet and outlet hoods that guide the gas streams across the appropriate section of the bundles. Heat transport between the cold and hot gas streams relies on the principle of isothermal evaporation and liquefaction of a working fluid, under vacuum conditions. The phase changes within each pipe results in high heat transfer coefficients. Every Ecostat exchanger is designed to process specific requirements and is customized to achieve the optimum number of tubes, tube orientation, combination of finned and unfinned tubes, and bundle arrangement (in series or parallel). The heat pipes can also be coated for service in corrosive environments.

Clients who use our Ecostat heat exchangers report the following advantages:

- Inherently safe, requiring no external safety or control systems due to the self-regulating nature and fast reaction time of the system.

- Simple plant geometry and compact design due to modular components (easy to assemble), that can be readily integrated into ducting.

- No cooling media or supporting systems, (e.g., water preparation, circulation, cooling, and condensate systems) are required.

- High operational reliability and availability due to inherent redundancy of multiple individual and independent working systems (bundles and pipes).

- Gas-tight, no leakage between the fluids with no cold or hot spots.

- Modest pressure losses, resulting in low gas stream motive energy requirements.

- Adaptability to client-specific process and operational needs, including material of construction with long life.

- No moving parts, eliminating the need for propulsion energy (e.g., pumps) and resulting in low maintenance requirements and ease of inspection.

- Low fouling and well suited for gas streams laden with particulates, and where dew point control is essential.

Benefits

With more than 200 successful WHR assignments completed across diverse applications ranging from iron & steel production, cement manufacture, the glass and food industry and utility sectors, partnering with us can lead to:

Lower operating cost and improved efficiency: Fuel consumption can be reduced and efficiency improved, delivering substantial cost savings.

Cost-effective emissions reduction: By consuming less fuel, CO2 emissions can be avoided, without the need for a complete overhaul of assets.

Operational profitability improvement: Lower operating cost, reduced emissions and the potential to export more useful energy can combine to provide strong justification for delivering positive, triple bottom line business outcomes.

From conceptualization to implementation, we tailor our solutions to the specific needs of our clients, ensuring seamless integration and long-term reliability.