Our goal is to monitor asset integrity and assess their condition and performance and ultimately assist the client in optimizing their maintenance, replacement or rebuild plans. We have developed multiple patented technologies to ensure safe and efficient operation throughout the lifecycle of various assets/structures. By continuously tracking the asset condition and key performance indicators (KPIs) like uptime, energy usage, maintenance needs, and output quality, organizations can detect and attend to issues in advance, reduce downtime, and optimize maintenance schedules. This proactive approach not only extends asset lifespan, but also minimizes operational costs and enhances productivity. Ultimately, our asset performance monitoring services enables data-driven decision-making, helping businesses achieve higher returns on investment and maintain a competitive edge in their industry.

Challenges

Keeping mechanical and structural assets in good working order is a constant challenge in metallurgical, energy, and infrastructure industries. Assets eventually deteriorate or become damaged during operations and must be retrofitted or replaced. Comprehensive inspection and monitoring techniques are needed to extend the service life of mechanical and structural assets and optimize maintenance schedules and productivity.Non-Destructive Testing (NDT) techniques and monitoring systems can be used to assess the condition and deterioration of mechanical and structural assets without intrusive instrumentation or damage to the assets. In many cases, NDT techniques can be applied without disrupting normal operations.

NDT has a wide range of benefits, including accident prevention, facilitation of maintenance planning, and optimization of efficiency and profitability. When applied regularly, NDT contributes to safer, more reliable assets, and greater profits for the companies that own the assets.

Capabilities

Acousto Ultrasonic-Echo (AU-E)

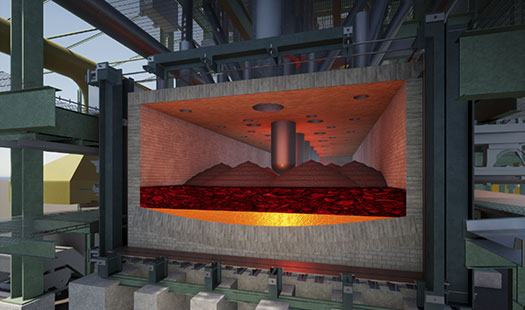

This Hatch-patented technique measures the thickness and condition of refractory linings in operational metallurgical process vessels. AU-E can be performed during vessel operation without disrupting the production schedule. It can detect refractory conditions such as remaining thickness, build-up thickness, and chemical alterations such as metal impregnation, metal penetration, hydration, and oxidation. Periodic AU-E measurements can assist the planning of repair and optimize refractory lining campaigns. It can also be used for determining the salamander tapping location of blast furnaces.

Radar feed-level measurement

This automatic feed level measurement system was developed by our experts based on electromagnetic waves. The patented system can accurately and continuously measure the top level of the concentrate or feed bank in metallurgical furnaces. Real-time feed-level measurement allows furnace operators to optimize the smelting process, reduce energy consumption, prevent premature damages of the furnace roof, and thus, can reduce maintenance costs, reduce furnace downtime, and increase profitability.

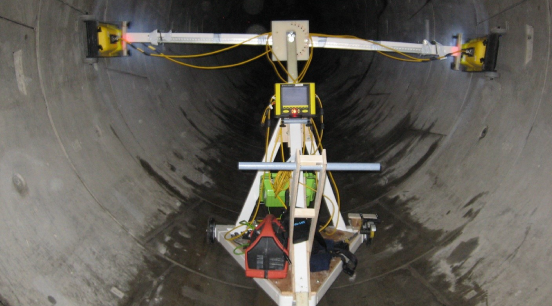

StaveCheck™

Another Hatch-patented technology known as the StaveCheck™ system (formerly called LFPU) can be used to measure the worn profile of cooling staves in blast furnaces. Developed in house by Hatch, the StaveCheck™ system utilizes low frequency ultrasonic waves determine the remaining stave thickness from the cold face of the furnace shell while the furnace is fully operational. It is a more advantageous solution to destructive drilling and conventional ultrasonic rod thickness measurements. StaveCheck™ is flexible and can measure any location of the stave, while the conventional techniques can only measure locations where ultrasonic rods were installed. By doing periodic measurements of the staves, we can develop wear trends for each stave and help blast furnace clients in prioritizing their stave replacement schedules.

ElectroDAR

This patented system determines the tip position of electrodes in electric arc furnaces.

It uses electromagnetic wave signals to continuously measure the electrode tip location during furnace operation.

The real-time electrode-tip-position measurement allows operators to maintain the desired power input, increase furnace efficiency, and produce a lower cost, and higher quality product.

Stray Current Measurement

This system allows the detection of cracks or initiation of cracks on rails. Early detection of cracks can ensure timely repair and maintenance to ensure rail safety. The stray current measurements are fast and can be done overnight while the railroad is not in use.

Taphole acoustic monitoring (TAM)

This Hatch-patented system monitors directional drilling, lancing, and tapping operations in metallurgical furnaces. TAM detects and locates acoustic emissions during furnace operations. Any directional lancing, and uneven wear of the taphole refractory lining is mapped as significant AE activities in real-time to provide the condition assessment of the tapholes. TAM can be used to enhance safe operation of tapblocks and optimize taphole campaign life.

Furnace Integrity Monitoring System (FIMS)

Our patented technique prevents and provides early warning of structural failures and run-outs in metallurgical furnaces. A system of sensors, it detects and maps acoustic emissions that may be caused by refractory movement and changes in the vessel integrity. FIMS can also be used to determine the remaining refractory thickness of the vessel.

Slag/ Matte Level Measurement

The Slag/ Matte Level Measurement system allows the direct measurement of the slag and matte level inside the furnace while in operation.

This is done through inserting a protected probe through the furnace roof into the slag/matte within the furnace.

Structural Health Monitoring (SHM)

Monitoring the health and integrity of large structures is key in ensuring long-term structure performance and safety. Hatch’s NDT group provides structural health monitoring (SHM) services for our clients across the infrastructure, metals, and energy sectors. SHM can be used to detect changes in characteristics of the structure, assess remaining performance capacity of structures, and gain understanding of stress distribution and the structure responses.

Some examples of the SHM services we provide include visual and NDT inspections, real-time monitoring of structures through wireless systems, along with stress and structural analysis.

Structural health monitoring systems can be installed on both new structures during the construction phase and existing structures during its operational life. The following structures can be monitored by SHM:

- Bridges

- Tunnels

- Dams

- Culverts

- Historical Structures

- Critical Buildings

- Wind Power Generators

- Mining Shafts, etc.

AE monitoring for leak detection:

Our AE monitoring system is used for continuous real-time monitoring of structures. We applied the system for the detection of acid leaks or water leaks in metallurgical vessels, tanks and pipes. This system can also be applied to infrastructure, such as cable stayed and suspension bridges, to detect initial signs of cracks on the tendons and cables.

Crack and Stress Monitoring:

We provide real-time wireless monitoring of structures with the ability to measure both stress through structural members and growth of identified surface cracks. The collected data can be viewed and analysed remotely allowing for rapid alerting and monitoring of any changes on site.

Other NDT Services to Determine Asset Integrity

We also customize solutions to determine the condition of concrete and steel structures, this may include the use of ground penetrating radar, impact echo, infrared thermography, magnetic particle inspection, ultrasonic inspection, and liquid penetrant inspection. Our customized NDT services are applicable to any infrastructure, including industrial assets, bridges, buildings, nuclear power plants, hydropower plants, oil and gas infrastructure, pipelines, metallurgical vessels, and assets. We customize solutions to suit site conditions and client requirements. Contact us for more details and let us assist you with customized solutions that is right for you.

I. Ground penetrating radar (GPR):

Locating and identifying underground utilities and underground pipe leakage. Determine concrete conditions including possible delamination or corrosion and detect voids behind structures. We customize the GPR solution to suit our clients needs.

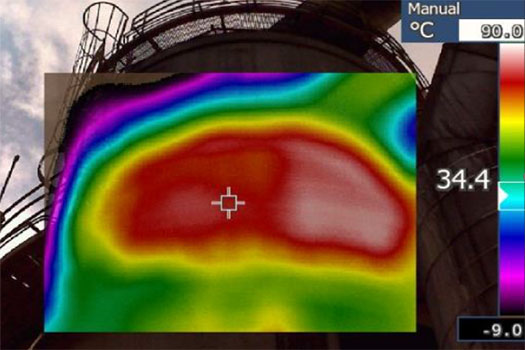

II. Infrared thermography:

Identify potential leak and corroded regions or pipes, vessels and concrete structures.

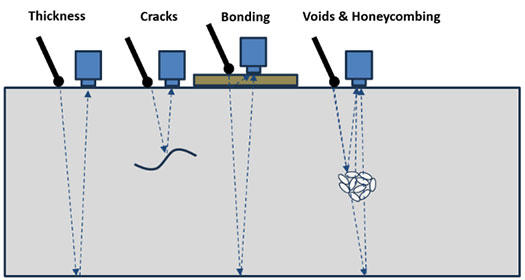

III. Impact Echo:

Measures the thickness or strength of concrete. Can locate concrete defects such as delaminations, voids, and cracks.

IV. Schmidt Hammer:

Quick measurement of concrete surface strength. Used in conjunction with other techniques for full evaluation of concrete integrity.

V. Ultrasonic Testing (UT/PAUT)

Ultrasonic Testing (UT) and Phased Array Ultrasonic Testing (PAUT) determines material thickness, evaluates internal defects such as cracks, delaminations inclusions, and voids in a wide variety of materials and features including welds. PAUT allows for increased flaw detection, faster inspections speeds, and wider range of possible applications.

VI. X-Ray Fluorescence (XRF)

Identifies the composition of test materials. Applications include quality control, material compliance, Geology/Mining, Environmental and soil Remediation.

VII. Magnetic Particle Testing

Detects surface and shallow subsurface discontinuities such as cracks. Applicable in ferromagnetic materials.

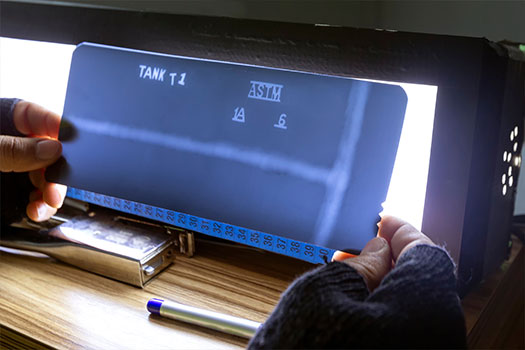

IX. Radiography

Examines internal structure and integrity of materials. Detects thickness and internal defects such as cracks, porosity, voids, and inclusions.

VIII. Liquid Penetrant Testing

Detects surface breaking discontinuities such as cracks, seams, or high porosity. Applicable in a wide variety of materials