Integrated operations are the modern approach to breaking down silos to improve decision making. Often, this involves having people co-located in an Integrated Remote Operations Center (IROC) where they remotely execute tasks away from where the physical activities are occurring.

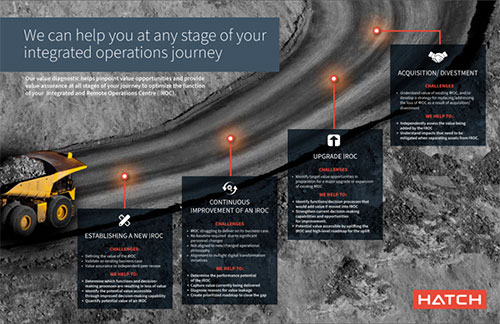

Our integrated solutions helps pin-point opportunities to provide value assurance at all stages of your journey, whether it be to:

- Conceive and implement new IROCs

- Rescue IROCs that are not delivering value

- Take existing world-class IROCs to the next level

Background

IROCs enable faster response and integrated decision making across the value chain, supporting functions and planning horizons; improving accuracy, responsiveness and quality of decisions whilst driving a culture of operational discipline and continuous improvement.

Organizations approach integrated operations and digitalization in many ways. We can help you define the right style of IROC for your company according to its business context, strategy, goals and needs.

Companies that add IROCs achieve an initial performance gain, but consistently suffer long-term from poor operating discipline. Our research indicates that existing IROCs experience multiple areas of value-loss, most commonly from limited decision-making capabilities, lack of alignment with the new ways of working and redefined role requirements. These factors highlight the importance of a continuous approach that monitors, updates, and provides insights to improve operations over time.

Your IROC partner at any stage of your journey

Hatch has been engaged in digitally-enabled IROC design and implementation for decades, under the mission of making the IROC deliver the maximum possible value.

What sets us apart:

Our dedicated IROC team unites with other specialists from within Hatch to bring you the right mix of capabilities.

Hatch offers a one-stop shop option for designing, implementing, or improving every facet of an IROC – people, process, place and technology.

We combine our Engineering Project Delivery capability with our tried and tested Operational Readiness methods, to de-risk the project and deliver value sooner.

Our holistic set of IROC offerings

Establishing a new IROC

Defining the IROC strategy, vision & roadmap and developing a business Case

Continuous Improvement of an IROC

Demonstrably and incrementally improving value delivery from IROCs (Value Diagnosis & Roadmap)

Upgrading a new IROC

Taking the existing IROC to the next level to match best-in-class (Benchmarking)

Integrated Operations

Digital Strategy & Roadmap, Integrated Planning & Scheduling, Value Chain Optimization, Benchmarking

Our IROC solutions have proven to deliver company-wide value

Up to 30% Incident reduction

Increased oversight as well as rapid response time to safety & evacuation time

25% Labour utilization

Improved operational efficiency and uptime, role consolidation

15% Performance improvement

Eliminate value leakage due to isolated decision making, establish best practices and ways of working

5-7% Equipment availability improvement

Faster maintenance response times and time for operators to re-enter repaired trucks

Interested in learning more?

70% of existing IROCs are under-utilized. Read about

Hatch's IROC findings to uncover why this is, how to

prevent it, and what we can do to help.