Removal of Phosphorus Technology Alternatives

Abstract

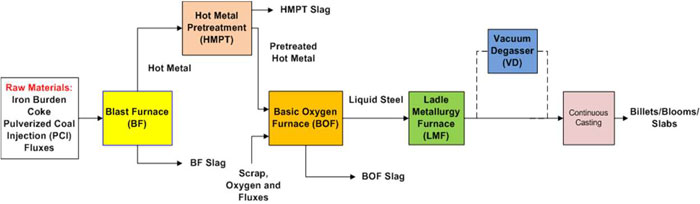

Phosphorus is a problematic impurity that has challenged steelmakers for decades. With increasing phosphorus in the available iron ore resources, steel producers developed specific technologies and practices to reduce phosphorus prior to and during BOF steelmaking. These process technologies reduce phosphorus to various degrees and generally increase the cost of making steel. This paper will focus on the blast furnace (BF)/ basic oxygen furnace (BOF) steelmaking route described in Figure 1 below.

Figure 1. Process Flow Diagram for the Blast Furnace (BF) / Basic Oxygen Furnace (BOF) Route

Demand for steel with improved physical and mechanical properties is increasing and many of these grades require low phosphorus content. A wide variety of steel products are produced with <0.02%P and some seamless pipe grades and plate grades require phosphorus <0.01%P. Case studies comparing six (6) process technologies to reduce phosphorus are described including the related treatment cost and final steel phosphorus content. Iron ore price penalties/premiums for P content; additional steel treatment costs and low-P steel price premiums are compared to put the cost of phosphorus removal into context. From this, suitable processing technologies to control P in a cost effective manner are identified to meet the growing demand for low phosphorus steel products.