The ramp-up series: Beyond the curves

Part 1: An update and new perspectives on the McNulty Curves for capital project success

The history

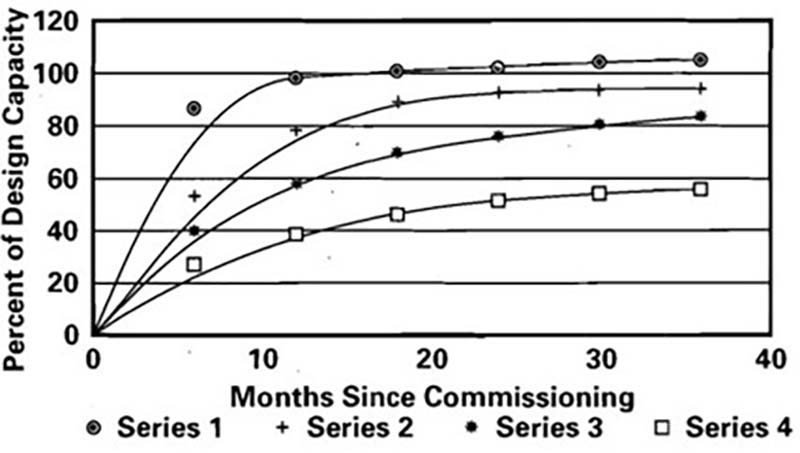

When McNulty’s original paper was published, project owners and engineers already sensed that ramp-up underperformance was common, but they lacked a systematic way to illustrate or compare it. McNulty’s contribution was to plot real-world mining projects against each other, distilling their ramp-up performance into a set of characteristic curves.

His 1998 data surveyed 41 metallurgical and chemical processing plant case histories, resulting in the creation of the four curves. Series 1 represents successful performance. Series 4 represents poor performance. [1, 2]

This provided, for the first time, a visual and quantitative way to describe what project owners had been experiencing anecdotally:

The four empirically-based curves represent four different ramp-up scenarios—or series. McNulty theorized that a project’s percent achievement of design capacity with respect to time since commissioning [1, 2] was attributed to characteristics, and understanding these characteristics could be used to determine the likelihood of delivering the expected performance.

The original McNulty curves gave structure to an uncomfortable truth: many projects underperform.

The value

McNulty’s paper struck a chord because it revealed patterns that practitioners recognized. It identified relevant relationships between project characteristics and their predicted outcomes; the maturity of the project’s technology and thorough testing of any potentially risky unit operations is considered alongside the project team’s phronesis.

In other words, the value of McNulty curves is identifying how project characteristics impact success in comparison to other projects. By situating a project’s performance against historic benchmarks, the curves provide a shared frame of reference to see if projects are on track. Owners gain an unflinching diagnostic.

Mining companies started to use the framework as a diagnostic tool, applying the curves to feasibility studies and reviews and shaping early discussions about the risk of “optimism bias” in ramp-up forecasting.

The curves are now widely used as a diagnostic tool by operating companies and project financing firms. By placing their projects on the curve to see if they’re “ahead” or “behind”, the curves provide a shared frame of reference in project delivery and inform risk assessments and financial decisions [3].

The application

- Mature technology previously used in successful projects.

- Detailed pilot scale testing completed.

- Prior existing licenses for applicable cases.

- Educated and informed workforce.

- Experienced and committed supervisory staff.

- Technical support during commissioning and ramp-up.

Has at least one of the following characteristics:

- If the unit operation is licensed, it was one of the first.

- Equipment was used as a prototype for size or application.

- Pilot plant testing is incomplete or completed using non-representative samples.

- Severe process conditions (high temperature, high pressure, or corrosivity).

- Simple operations, like materials handling, aren’t carefully engineered.

Same characteristics of Series 2, and some of the following:

- Extremely limited pilot plant testing that doesn’t address all important process steps.

- Feed characteristics aren’t well understood.

- Product quality is neglected throughout process development.

- Significant design flaws.

- Engineering, design, and construction were fast-tracked.

Shares characteristics with Series 2 and 3, plus additional issues:

- If any pilot testing is completed, it doesn’t account for process parameters.

- Equipment is downsized or design criteria is adjusted to be less conservative.

- Complex process flowsheets with prototype equipment in 2+ critical unit operations.

- Process chemistry is not understood.

Owners need a holistic understanding of the driving forces behind projects and characteristics supporting Series 1 performance. To do this, it’s important to ask: Can project ramp-up be better than Series 1?

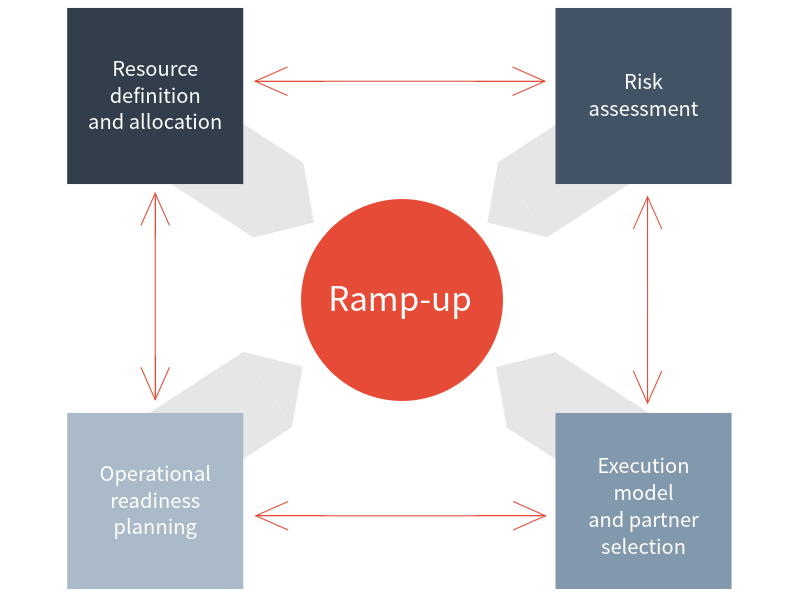

There’s a risk in not recognizing the possibility of having a ramp-up that is better, especially in instances where several projects are competing for financing. A fast ramp-up can be achieved if a project owner has done a thorough job of all stages of project development:

But recent years have revealed another hard truth: ramp-up success can hinge on factors outside of owners’ control. Stable geopolitics, an educated and well-trained workforce, experienced and supportive partners, and the impacts of technical maturity all shape new perspectives on the ramp-up curves.

What’s next?

To keep the curves applicable and relevant in a new era of project delivery, we must now apply the lessons we’ve learned the hard way to a new era of projects—one that extends beyond the limits and hindrances that halted earlier owners in their tracks to achieve project success.

The ramp-up series: Beyond the curves will share insights on how to get there. Hatch’s subject matter experts have joined forces with Dr. Terry McNulty and Dr. Phillip Mackey to explore the latest ramp-up and project delivery best practices and how to apply them to industrial projects across all sectors. Together we dive into:

Informed risk-taking

Megaproject governance

Achieving excellence in ramp-up

De-bottlenecking studies and upgrades

Innovation in engineering

Breakthrough contributions in metallurgical operations

Planning for success

The ramp-up series: Beyond the curves will reveal our new perspectives and research at Extraction 2025. Join Hatch as we dive deep alongside McNulty and Mackey and take a cross-sector look at how the new perspectives will be applied to achieve largescale industrial project success.

References

[1] McNulty, T. (1998) Innovative technology: its development and commercialization. In: Kuhn M (ed) Managing innovation in the minerals industry. SME: 1-14.

[2] McNulty, T. “Developing Innovative Technology”, Mining Engineering, vol. 50, no. 10, October 1998, pages 50-55.

[3] R. Beauprie and A. McKen, Cote Gold: From first gold to commercial production and beyond, Paper presented to the 57th Annual Meeting of The Canadian Mineral Processors Ottawa, Ontario, Canada, 21-23 January 2025, The Canadian Institute of Mining, Metallurgy and Petroleum, 2025.

About the authors

Brittany MacKinnon

Britt MacKinnon completed her Applied Sciences degree in Chemical Engineering and Certificate in Business at Queen’s University in 2019. Since joining Hatch, Britt has worked with the Pyrometallurgy sector practice, Hydrometallurgy sector practice, Mining sector practice, and Advisory team on various studies and programs. Britt enjoys collaborating with others to find innovative solutions to challenges, especially about how to create a more sustainable mining and metals processing industry. Britt has earned her P. Eng and she was invited back to Queen’s University to deliver the keynote about the importance of ethics in engineering. Her work has taken her across the globe to Brisbane, Australia, for nearly two years, beginning in 2023, then she was assigned to North Carolina, USA to serve as a process engineer on site, and recently she has returned to Hatch’s headquarters in Mississauga, Ontario, Canada.

Britt serves on the MetSoc Board of Directors as the Sustainability Section Chair. Britt was recognized with a 2021 Association for Iron & Steel Technology (AIST) Presidential Citation for her “contributions as a Young Professional and rising leader in AIST”. AIST is the global leader in networking, education and sustainability programs for advancing iron and steel technology.

Terence (Terry) McNulty

Dr. Terry McNulty is a metallurgical engineer with degrees from Stanford University, Montana Tech, and the Colorado School of Mines. A registered professional engineer, he spent 20 years at the Anaconda Company and later held executive roles at Kerr-McGee Chemical and Hazen Research. In 1988, he co-founded T. P. McNulty and Associates, a global consulting firm. Terry holds two patents in copper metallurgy and has published over 50 technical works. He is a member of several professional societies and was elected to the National Academy of Engineering in 2005. His numerous honors include the Robert H. Richards Award and Distinguished Alumni Awards from Colorado School of Mines and Montana Tech.

Phillip Mackey

Dr. Phillip Mackey is a globally recognized metallurgist known for pioneering copper smelting technologies, including the Noranda Reactor and Converting Processes, which have transformed non-ferrous metallurgy worldwide. Originally from Australia, he earned his BSc and PhD from the University of New South Wales before moving to Canada, where he led innovations at Noranda and later Xstrata. Mackey has authored over 100 technical papers, mentored future metallurgists at Laurentian and McGill, and served as an honorary professor in China. A Fellow of CIM and TMS, his numerous accolades include the Airey Award and the Noranda Technology Award. He continues to contribute through global consulting and board service.