Fusion’s helium challenge: Designing the infrastructure to power the future

Why helium matters

Helium plays a dual role in fusion systems as a by-product and a vital enabler. Inside the plasma, helium is akin to ash, and is left behind from the fusion of hydrogen isotopes. If not carefully extracted, it hinders further reactions.

Outside the plasma, however, helium becomes indispensable. Its high thermal capacity, and chemical inertness make it an ideal gas for cooling high-temperature, plasma-facing walls and its low temperature performance for cooling cryogenic superconducting magnets. Our focus here will be as a high-temperature coolant for tokamak or stellarator magnetic confinement fusion systems.

Yet helium is far from abundant. Demand continues to climb across sectors—from high-temperature fission reactors to semiconductor manufacturing and medical imaging—while supply remains geologically constrained with complex refinement processes. As prices climb, helium has become a strategic resource.

Design with limits in mind

Once helium has been selected as a coolant, the cooling system design is often deprioritized as a conventional system in early fusion design phases, overshadowed by more novel or costly components. But underestimating helium’s importance and complexities will lead to an ineffective and over-constrained cooling system. Helium is capable, but only achieves its full potential through intentional, integrated, and iterative engineering. When combined with experienced designers, these coolant systems can be kept simple and effective.

A common pitfall in early designs is the use of a basic cascading high-to-low pressure tank system. Though simple in concept, these setups produce highly transient thermo-fluidic parameters with continuous expansion and compression cycles affecting system performance.

While tolerable at lab or perhaps even pilot scale, this approach often breaks down when scaled to larger commercial systems—driving inefficiencies, bloated helium inventories, and major cost escalations.

A steady-state design, informed by detailed non-ideal fluid dynamic modelling, often offers a better path forward. While helium’s low density and high velocity introduces complex compressibility effects that negate simplified models, the investment can pay dividends. When such helium coolant systems are also designed early in the process, they can actually facilitate the design of magnet and plasma-facing components, resulting in streamlined progression, lower costs and/or performance gains across design phases and test campaigns.

The tight space between extremes

In actualizing major fusion projects, physical space inevitably emerges as one of the defining constraints as it directly correlates to capital cost.

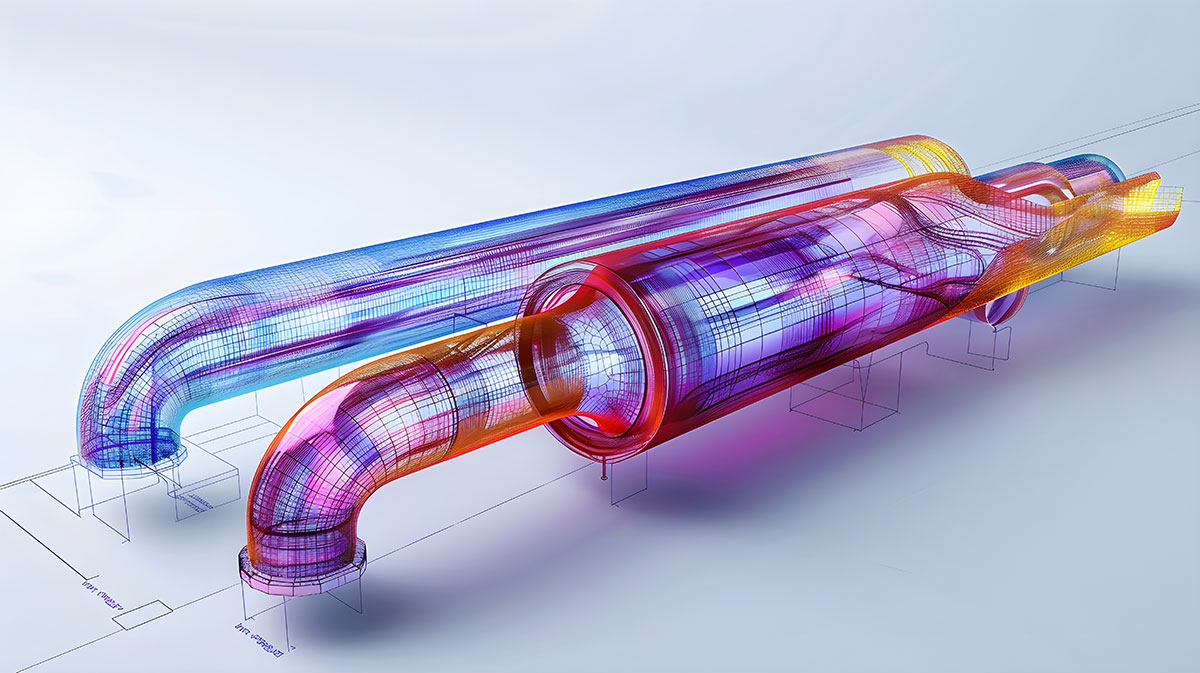

This is especially true for helium cooling designs. These systems must operate in the narrow corridor between superheated plasma and cryogenically cooled magnets. Larger pipes increase the helium system efficiency, but the larger separation is then detrimental to the more costly magnet systems.

As a result, coolant lines are inevitably kept small and routed through gaps often measured incrementally by millimeters, where valves can’t fit and flow must be managed passively.

Consequently, precision heat mapping of the plasma and detailed thermo-fluidic helium modeling are required. This minimizes compressor demand and mitigates damage to plasma-facing surfaces that would otherwise require lengthy repairs.

Pressure drop through piping also remains a critical factor. Since losses scale to the square of gas velocity, narrow pipes quickly increase the size and power of the system’s most expensive component, its compressor(s). Alternate layouts, such as shorter pipe runs with more header connections, can introduce vacuum integrity risks.

From design to delivery: Where the industry’s heading

The world needs clean, reliable energy—and fusion holds extraordinary promise. But even the most elegant designs on paper mean little if they can’t be constructed.

Construction planning is as important as the design itself. To minimize helium leakage, which can become a safety concern or render fusion device vacuum and magnet systems ineffective, piping must be seamless and ideally have welded joints throughout. But spatial constraints often rule out manual or robotic welding in the field which is needed for the kilometers of pipes and thousands of connections.

The solution lies in modular construction. Pre-assembled units delivered using standard transportation methods and integrated on site with precision. As one of Hatch’s differentiators, this core technique combines rigorous design, multidisciplinary expertise, and resolute honesty about what will work and how we will get there.

Designing effective helium systems may be just one piece of the fusion puzzle, but it’s representative of the broader complexity and ingenuity required to make sustainable fusion energy viable. Clean energy is imperative. We thrive at the intersection where physics meets engineering, where theory meets construction, and where ambition meets execution. Our engineers are looking to solve the toughest challenges and build practical solutions—safely, sustainably, and at scale.

Contact us to learn how we partner with organizations to develop new technologies, such as fusion energy, to generate positive change and innovation across the globe.

We’re ready to do this, together.

Read Part 1 of Steven’s series here.