Key trends shaping the mining and metals sector in Southern Africa, Part 2: Digital

The implementation of digital tools has created a shift in the way of working, most notably in the reduction of the management information gap, which is moving from reactive reporting to proactive actions and ultimately resulting in faster decision-making.

A series of building blocks are needed to operationalize digital initiatives such as sensors, networks, platforms, and analytics. However, the value of digital is only realized when it leads to better and faster decision-making such as the reallocation of equipment or changing of plant set-points in real time.

The challenge is that only 30% of digital transformations succeed, as they are often driven by taking a shotgun approach, rather than by embedding solutions into ways of working and aligning solutions with value.

This observation has been echoed from industry executives claiming that digitization has been approached haphazardly, that the overall vision and strategy lacks clarity, and that point-solutions are being deployed without an understanding of the impact on people and processes.

Companies that deliver their digital transformation successfully tend to focus on six key factors:

- A clear strategy and vision that aligns operations objectives with digital capabilities and opportunities.

- The identification of value cases that impact operational decision levers.

- The combination of data-driven recommendations with expert knowledge for optimal decisions.

- Implementation at scale with enterprise-grade solutions ready for operations deployment.

- Clarification of analytical recommendations that build the “human-machine” partnership.

- Deployment of the full life cycle of the asset.

By setting clear parameters surrounding ambition and approach, organizations can operationalize these factors and align initial launch with scaled roll-out and execution.

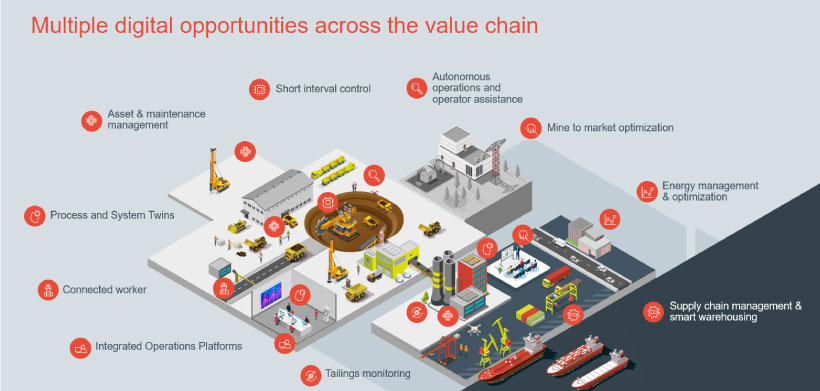

The ambition phase is aimed at taking stock of current initiatives, understanding value, and informing a set of use cases. We have seen an expanded portfolio of use cases across the value chain. These include effective asset management through digital and predictive maintenance; improved operational decision-making and operating stabilities through digital twins; advanced process controls; and the management of catastrophic risk- and environmental-impact through digitization in tailings management and rehabilitations.

Multiple digital opportunities across the value chain

Integrated operations

Companies can experience challenges with integrated operations due to a lack of clarity on decision rights across the operations and limited in-shift optimization. This leads to a reactive view on Key Performance Indicators (KPIs) and operational performance.

These challenges can be addressed by the implementation of an Integrated Remote Operation Centre (IROC), which provides real-time monitoring of all operational KPIs across the value chain and operations. Performed by specialists with experience in cross-functional co-ordination and issue resolution, this results in integrated planning and performance reporting while increasing production throughput by 10 – 20%, reducing operating costs by at least 3%.

Processing twins

The deployment of digital twin technology can address challenges faced in process performance such as the reliance on operator knowledge and experience, variability in operator performance across shifts, and delay in process adjustments due to feed variability; all of which can lead to inconsistent production. Processing and smelting digital twins can provide a central view and repository of historical operating conditions, creating real-time insights and process adjustments to balance feed, process controls, and target production output. Digital twin technologies have been seen to deliver significant value of 10 – 20% campaign life improvement and $5.00 – $10.00/t reduction in production cost.

System twin mine-to-market optimization

Some organizations are also experiencing challenges in managing their value chain due to decentralized data resources, isolated planning tools, and insufficient production scenario planning, with simplified optimization methodologies also contributing to the complexity of operations.

A mine-to-market optimization tool can address this by providing a multi-objective decision-making feature to minimize operating costs while ensuring operational, quality, and decarbonization targets are met. These platforms provide the best blending strategies in the case of stockpile optimization, delivering significant value improvement of $0.5 – $1.00/t.

Part 3 of this blog series will discuss resilience in an uncertain business environment and the need for organizations to adapt to business landscapes with more disruption and risk than before. Contact Hatch for further information on growth and portfolio diversification and to find out more about how they are shaping the mining and metals sector in Southern Africa.

Click here to view Part 1 of the series: Growth and portfolio diversification.

Jaco Van Niekerk

Principal, Advisory

With over 24 years’ experience in operations management and advisory, Jaco successfully delivered large scale business transformations and operational excellence. Over the past 10 years, he expanded his experience into information management, by delivering Digital Transformation in Mining. Qualified as a Mechanical Engineer, Jaco has a keen interest in predictive asset management, guiding mining clients to define the future of asset performance management.